|

|||

|

|

|||

|

Page Title:

TABLE 6-1. WEAR LIMITS AND CLEARANCES |

|

||

| ||||||||||

|

|

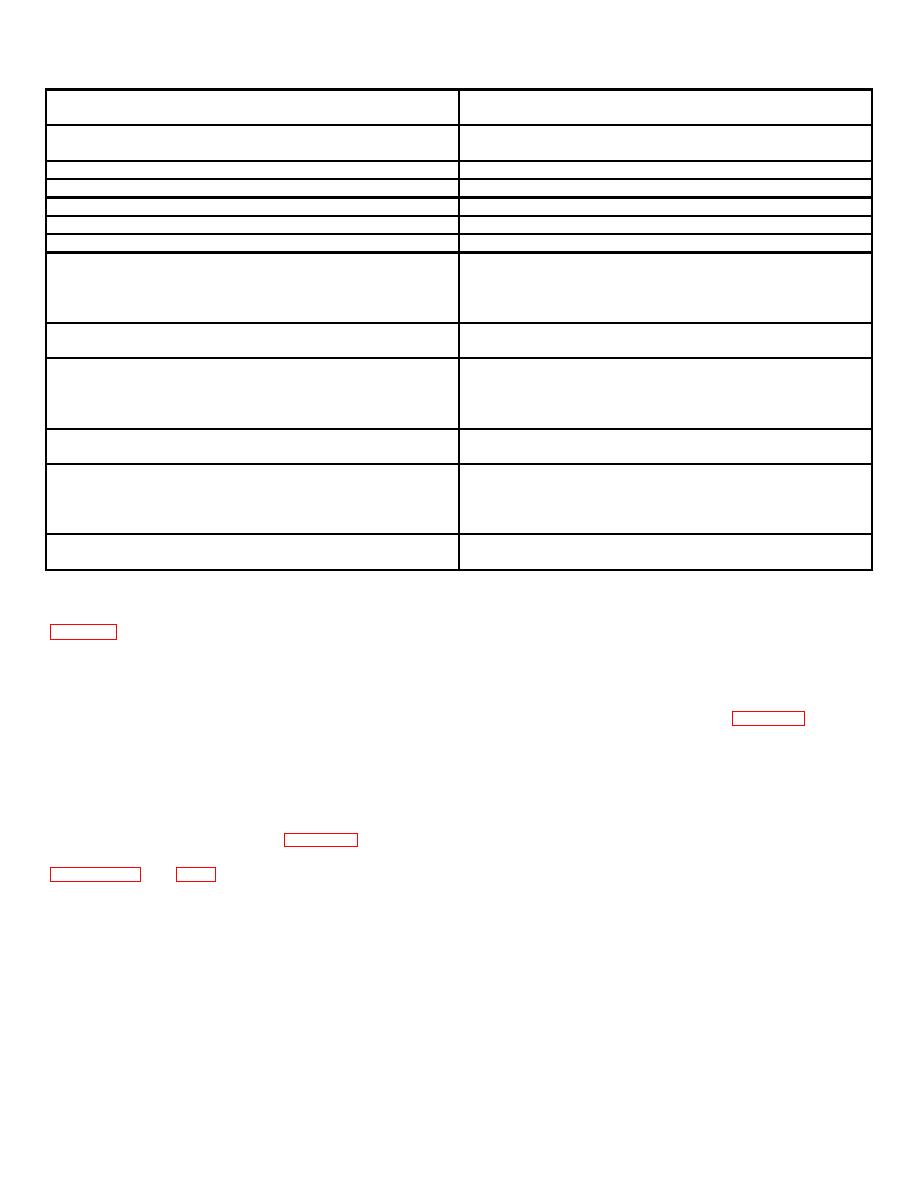

TABLE 6-1. WEAR LIMITS AND CLEARANCES

Drive axle - axle shaft

0.003 inch maximum, total

run out

indicator reading

Drive axle - differential

0.000 to 0.003 inch loose

preload

Adapter - input gear backlash

0.006 to 0.008 inch

Motor brake shoes

1/16 inch minimum thickness

Service brake shoes

1/16 inch minimum thickness

Steering gear - lash adjuster

0.002 inch end play maximum

Travel motor - brushes

3/4 inch minimum length

Travel motor - armature

4.375 inches minimum diameter,

commutator

16 microinch rms surface

roughness, 3/64 inch deep by

0.030 inch wide undercutting

Hydraulic pump motor

-1/2 inch minimum length

brushes

Hydraulic pump motor -

2.375 inches minimum diameter,

armature

16 microinch rms surface

roughness, 3/64 inch deep by

0.025 inch wide undercutting

Power steering motor -

1/2 inch minimum length

brushes

Power steering motor -

1.500 inches minimum diameter,

armature

16 microinch rms surface

roughness, 3/64 inch deep by

0.020 inch wide undercutting

Tires

3/4 inch minimum thickness

(approximately)

observed, consult the corresponding or most closely

6-14.

TESTING SCR'S AND DIODES. It is not

associated symptom listed in the left hand column of

necessary to remove these components from the

chassis for testing. Proceed as follows:

note the listing of the probable causes, and conduct the

corrective actions given.

1.

For power diodes (1REC, 2REC and 3REC),

6-12.

TECHNIQUES.

remove anode cable connection and connect continuity

test light in diode circuit as shown in figure 6-1a. A good

diode will light test light when connection is made in one

6-13.

These techniques are primarily used for

direction and not light when connection is reversed. If

locating defects in the electric power control circuit, and

test light lights in both connections, diode is defective

stress the approach of using continuity checks

and must be replaced.

(ohmmeter or test light) to determine the condition of a

component part. When checking electrical or electronic

2.

For SCR'S (1SCR and 2SCR), remove

components, and unless otherwise stated, always

cathode cable and white gate lead. Connect test light as

disconnect the battery connector. Table 6-3 provides a

shown in figure 6-lb.

Next, reverse test light

list of the test equipment required in servicing. Consult

connections. In each test, test light should not light. If

light comes on, SCR is shorted and must be replaced.

connections.

6-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |