|

|||

|

|

|||

|

Page Title:

Section XIII. OVERHAUL AND REPAIR OF PUMP MOTOR |

|

||

| ||||||||||

|

|

TM 10-3930-609-35

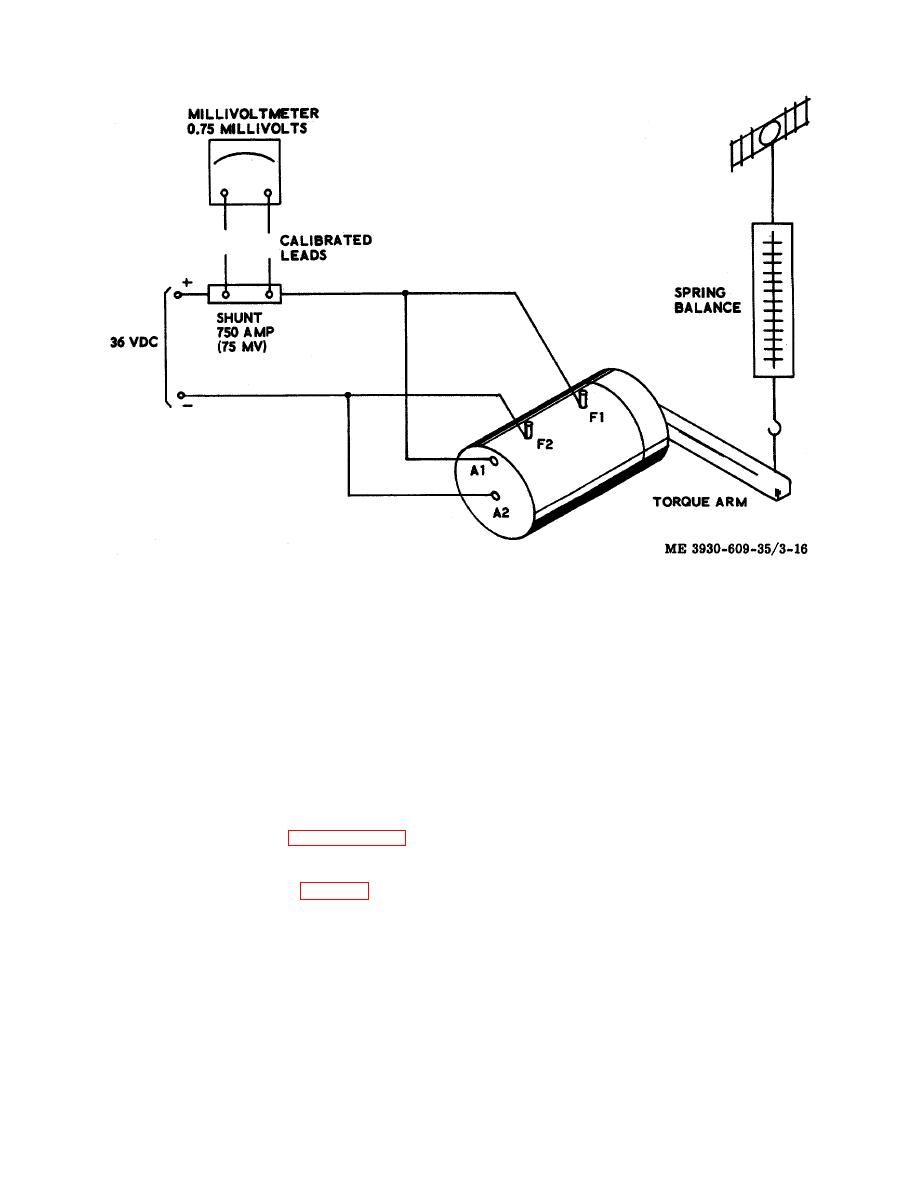

Figure 3-16. Travel motor test setup.

Section XIII. OVERHAUL AND REPAIR OF PUMP MOTOR

3-91. Description of Pump Motor

c. Remove machine screws and lockwashers

The pump motor is a four-pole, series parallel

which secure bearing retainer in rear yoke and withdraw

connected, spark enclosed, dc motor capable of

bearing retainer from yoke.

approximately 2.2 horsepower output when energized at

d. Carefully examine front yoke, motor ring and

36 volts. The armature shaft is ball bearing mounted at

rear yoke for match marks. If no match marks are

both ends.

evident, lightly mark parts with punch or chisel before

proceeding.

3-92. Removal of Pump Motor

e. Remove retaining ring from groove in rear end

Removal of the pump motor from the truck will be

of armature shaft.

required for overhaul and repair as described in the

following instructions. Refer to paragraph 2-22 for

secure rear yoke to motor ring; then, carefully withdraw

removal procedure.

rear yoke and remove ball bearing from rear yoke.

g. Remove retaining -ring from groove in front end

3-93. Disassembly of Pump Motor (fig. 3-17)

of armature shaft and carefully remove armature from

a. Remove capscrew, nut and lockwasher which

motor ring.

secure covers to front yoke; then, disengage covers

h. Remove jamnuts, insulating washers and

from studs in front yoke and remove covers.

flatwashers from field terminal and armature terminal;

b. Remove cotterpins from brushholders; then,

then, remove external insulator, insulating washers and

remove machine screws, lockwashers and flatwashers

bushings from terminals.

which secure brush shunts and jumpers to brushholders

i. Remove field terminal, insulating plate and

and remove brush springs and brushes from

insulating washer from inside front yoke.

brushholders.

3-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |