|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

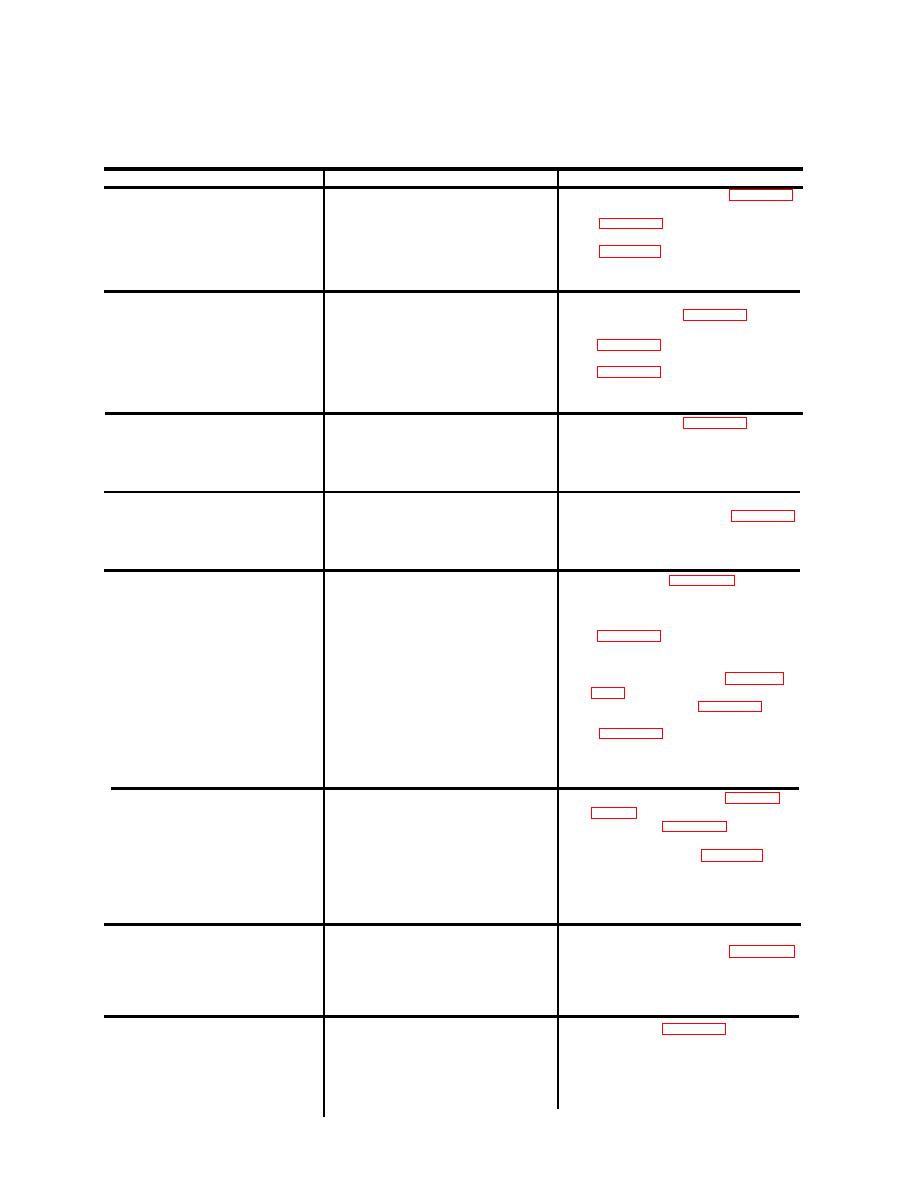

TM 10-3930-609-12

Corrective action

Malfunction

Probable cause

g. Seat switch not working.

h. Clean and secure connections firmly

h. Open circuit due to loose connections

in accelerator master assembly.

i. Replace accelerator master assembly

i. Mechanical binding in accelerator

master assembly.

j. Refer other causes to direct and gen-

j. Other causes.

eral support maintenance personnel.

a. Remove object.

a. Object lodged in relay.

2. All speeds not obtainable.

b. Dirty contacts on relay.

c. Replace accelerator master assembly.

c. Switches in accelerator master assem-

bly malfunctioning.

d. Replace accelerator master assembly

d. Sticking or binding of accelerator

any part of stroke.

e. Refer other causes to direct and gen-

e. Other causes.

eral support maintenance personnel.

3. overheating.

b. No technical remedy. Advise opera-

b. Vehicle operating in low speed for

tor to avoid practice if possible.

prolonged periods.

c. Refer other causes to direct and gen-

c. Other causes.

eral support maintenance personnel.

a. Clean unit thoroughly.

4.

Improper plugging control and

b. Dirty contact in relay.

timing through all speeds.

c. Refer other causes to direct and gen-

c. Other causes.

eral support maintenance person-

nel.

a. Improper brake adjustment.

5. Brakes dragging.

b. Open wheel cylinder bleeder fitting.

b. Plugged master cylinder compensat-

If brakes release when fluid es

ing port.

capes, replace master cylinder

e. Seat brake improperly adjusted.

c. Adjust so that brake does not drag

when seat is down and is firmly

applied when seat is up (para 3-

d. Mineral oil in brake system.

e. Brake return spring weak or broken

e. Replace brake system return spring

f. Other causes.

f. Refer other causes to direct and gen-

eral support maintenance person-

nel.

6.

a. W orn lining.

Brake pedal goes to floor.

b.

Air in system.

c.

Fluid low in master cylinder.

c. Replenish fluid and chock for leaks.

d.

Pedal improperly adjusted.

e.

Broken brake line.

e. Replace brake line.

f.

other causes.

f. Refer other causes to direct and gen-

eral support maintenance person-

nel.

7.

Brake pedal under pressure

a. Leaks in hydraulic brake system.

a. Locate and eliminate leaks.

gradually goes to floor plate.

b. Scored master cylinder barrel or

defective cup.

c. other causes.

c. Refer other causes to direct and gen-

eral support maintenance person-

nel.

8.

Brake pedal has springy or rub-

a. Air in system.

bery action.

b. Other causes.

b. Refer other causes to direct and gen-

eral support maintenance person-

nel.

3-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |