|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

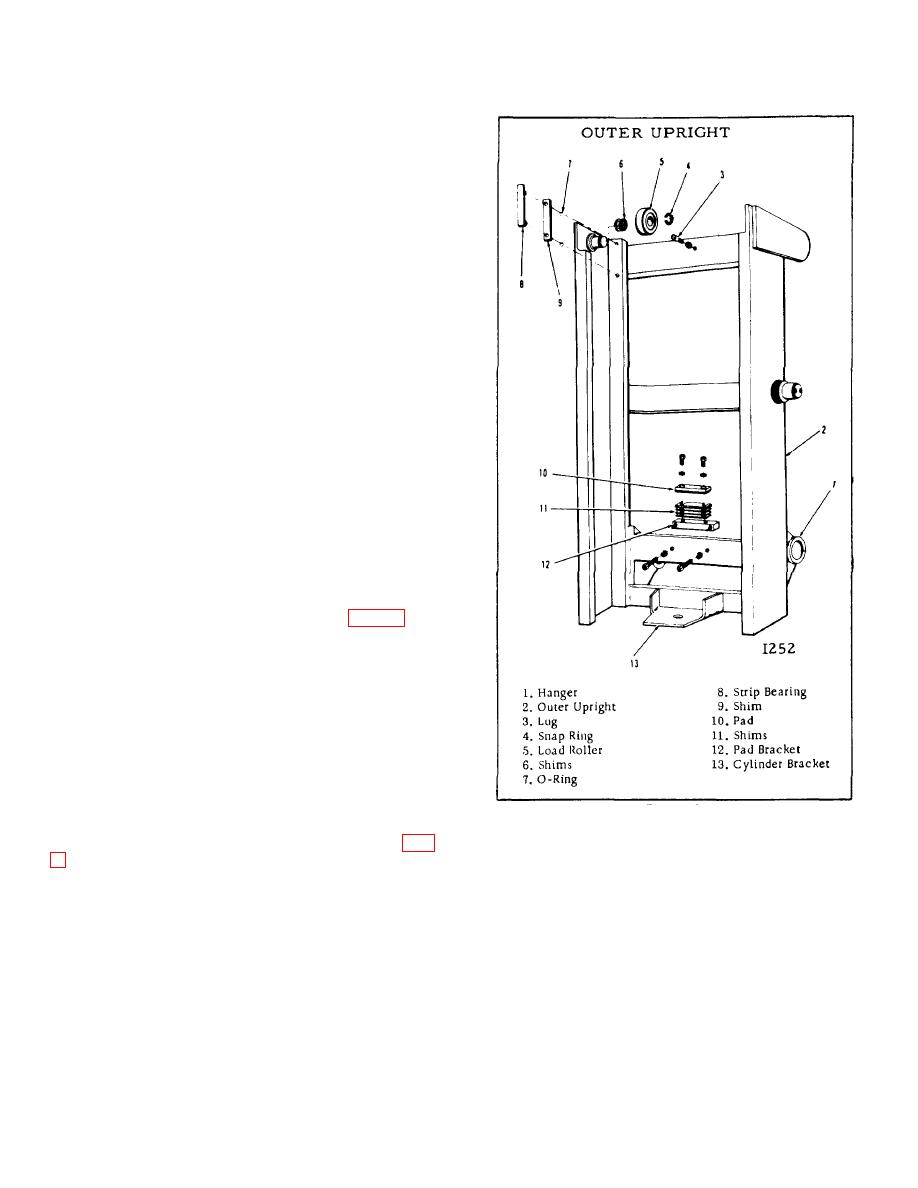

UPRIGHTS

inch) check for too much side play in the latch

shaft. If little side play is noticeable, the carriage

position with respect to the inner upright must be

changed.

IMPORTANT: When placing the lug closer to or farther

away from the latch, all the shim packs of the load

rollers are altered. In altering the packs, remember the

following: (1) When shims are removed from one side

of a load roller, they must be placed on the other side of

the same roller. (2) Alter the shim packs of all the load

rollers on a given side of the carriage the same; that is,

if a .030 inch shim was removed from the outer side and

placed on the inner side of the lower roller on the right

vertical member, alter the pack of each of the two upper

rollers on the right vertical member by transposing a

.030 shim. (3) Whenever shims are removed from the

outer side of and placed on the inner side of the rollers

on the right vertical member, the opposite must be done

to shim packs on the left vertical member and vice

versa.

UPRIGHTS

A. GENERAL

Latches and latch lugs (socket head capscrews) are

utilized to maintain the proper operating sequence of the

upright assembly, by securing the inner upright to the

outer and releasing it at the proper time. (Figs. 6 and

7).

There are three latches and two lugs, which make up the

latching mechanism. The latches are located at the top

of the inner upright. One of the lugs is located on the

back of the upper crossmember of the carriage. The

other is in front of the upper crossmember of the outer

upright.

Attached to the top of the hoist cylinder is a crosshead

and cylinder guide assembly. The guide, which is shim-

Figure 6.

adjusted, slides in two guide rails. One guide rail is

welded to the back of each outer upright channel. (Fig.

top of each outer upright channel. The other two are at

the bottom of the inner channels. The rollers are

equipped with sealed ball bearings, lubricated for life

Taking the load and side thrust imposed on the uprights

and replaced as an assembly.

are four canted load rollers. One roller is located at the

B-171

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |