|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

STEERING

lubrication

and

inspection

for

looseness. Looseness due to wear

is determined by grasping the tie rod

and attempting to move it relative to

the stud.

SPINDLE (Fig. 4)

A. REMOVAL

1. Remove wheel. Disconnect the tie rod. Unscrew

nut from king pin retainer pin. (Fig. 4) Knock out

retainer pin.

2. Remove the bearing cap (Fig. 4) or break out

the end of the upper needle bearing; then, using a bar of

slightly smaller diameter than king pin and hammer,

Figure 10.

drive out king pin.

3. Remove the spindle and remainder of the upper

5. Install upper bearing. Secure king pin by driving

bearing. Remove lower bearing if end was broken out

retaining pin into position, and securing it with the nut.

during king pin removal.

NOTE:

B. INSTALLATION

Install upper and lower bearings, flush with

inner surfaces of the axle arms. (Fig. 7)

1. Lubricate all parts before installing. Place

spindle and thrust bearing in position. Thrust bearing is

SUPPORT BEARINGS

placed between the spindle and axle upper member.

A. REMOVAL

2. Align spindle, thrust bearing and axle bore. Push

king pin into position until the retainer pin holes are

1. Raise truck sufficiently to remove pressure on stub

indexed with those of the spindle.

shafts. Mark front and rear caps.

3. Push retaining pin into bore sufficiently to hold

2. Pry axle to the rear (Fig. 11) and measure between

king pin to position.

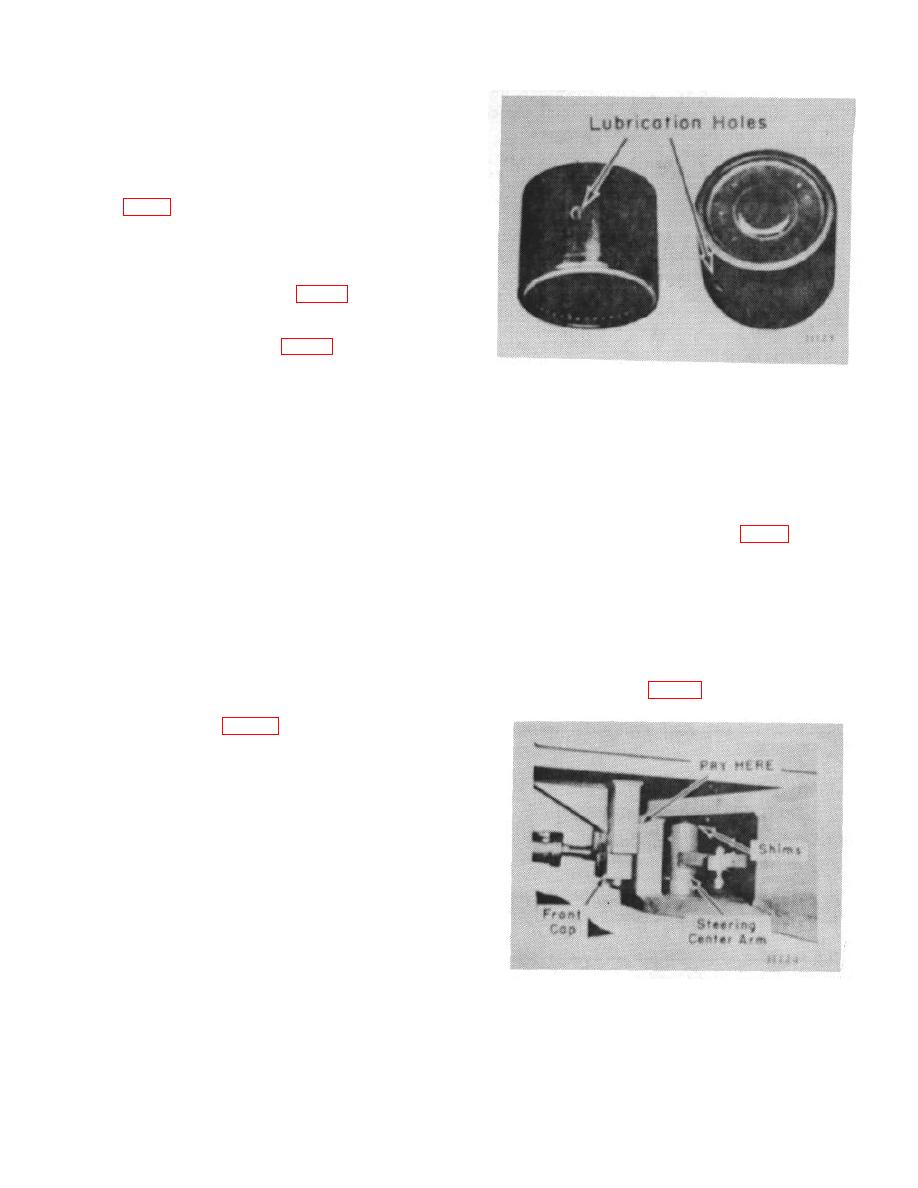

4. Align lube holes (Fig. 10) of the lower bearing

with grease fitting on spindle. Press lower pin bearing

into place until bearing end almost contacts the king pin

surface. The bearing can be pressed into position by

placing a jack under the bearing and axle.

CAUTION:

Whenever needle bearings are removed, they

must be replaced with new ones. Do not use

old bearings as microscopic damage occurs

during removal.

Figure 11.

B-163

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |