|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

BRAKES

3. Make sure the rubber boot is in position on the

Using a spare push rod, work the piston through its

push rod and master cylinder. This is important,

entire stroke until fluid is forced from the fitting end of

otherwise, dirt and water can enter the master cylinder

the cylinder. After fluid begins to flow from the fitting,

bore, causing premature failure.

continue to work the piston until at least 1/4 pint of fluid

is expelled from the fitting hole.

Throughout the

purging, keep sufficient fluid in the reservoir to prevent

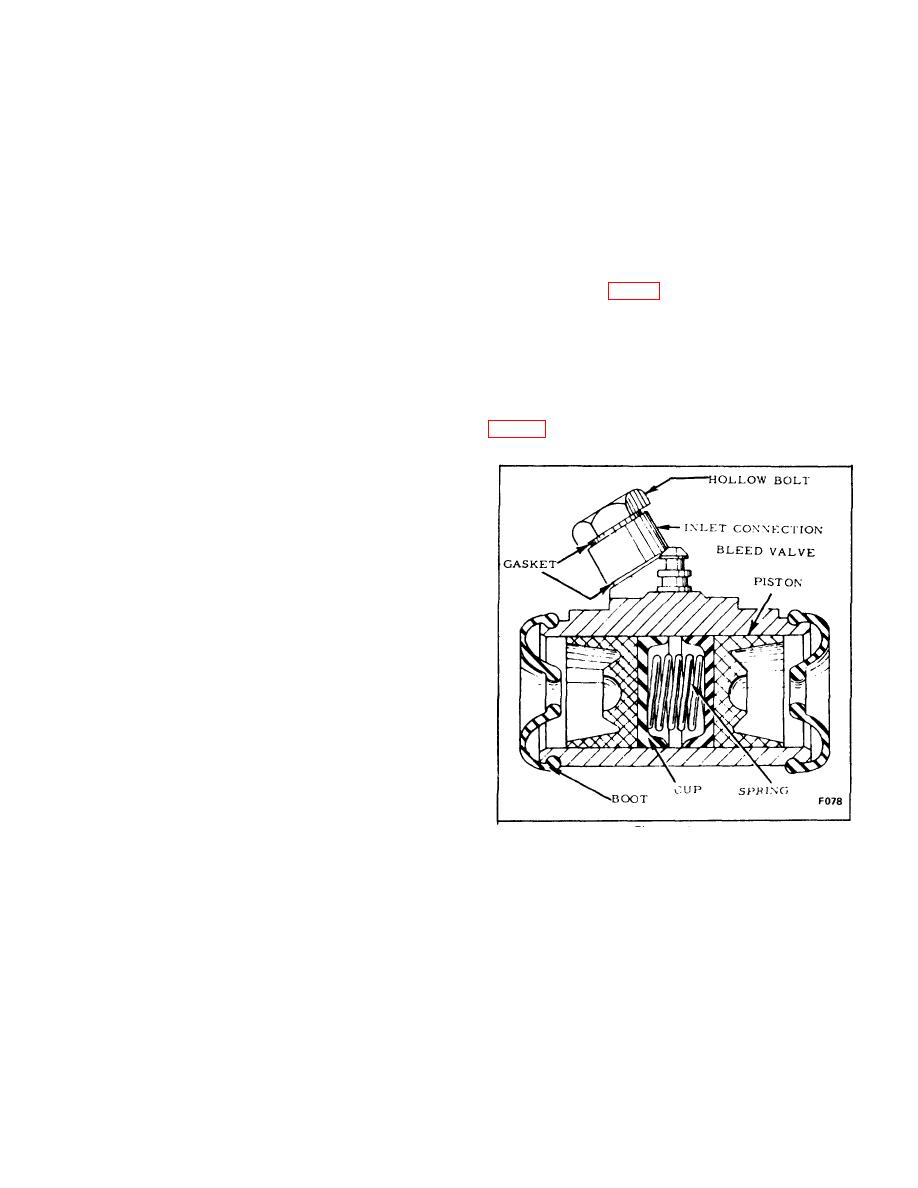

WHEEL CYLINDER

air from being pumped into the cylinder.

A. GENERAL

There are two cylinders on each truck. One in each

3. Cap fitting end of cylinder. Then fill reservoir.

brake assembly. (Fig. 6) Their purpose is to change

hydraulic flow and pressure to the mechanical

4. Place a new gasket on the filler cap and screw

equivalents.

the cap into the reservoir.

The wheel cylinder houses two opposed pistons, two

rubber cups and a spring. On the outside of the cylinder

F. INSTALLATION

is a bleed valve, hydraulic line fitting and two rubber

boots.

1. Install master cylinder using the reverse of

removal procedure. To prevent an aerated system,

tighten the line to master cylinder fitting while

depressing the brake pedal.

2. Adjust the master cylinder.

G. ADJUSTMENT

1. Adjust the adjustable link with pedal back until

cylinder push rod contacts the piston in the master

cylinder.

2. Check the pedal free-travel. Check inching.

NOTE: If the pedal linkage does not provide proper

clearance between the master cyl-, inder piston and the

linkage with brakes released, the piston cannot return to

full "off" position and the primary cup lip will seal the

cylinder by-pass port. Then the compensating feature of

the master cylinder cannot function and surplus fluid

Figure 13.

cannot return from the brake lines. Brakes will drag

after several applications if the by-pass port is blocked.

Although not utilizing the same drilled passages, the line

fitting and bleeder valve are in communication with the

cylinder bore in this manner.

B-135

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |