|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

BRAKES

increased to .005 inch over standard. Pressure marks

and discolorations 'may be polished out with crocus

cloth. Make sure intake and by-pass ports are open.

The by-pass port may be probed with a soft iron wire.

NOTE: Burrs in the by-pass port are caused cy

honing the cylinder wall and probing the by-pass

port.

These must be removed, otherwise, the

primary cup may be damaged during assembly or

brake operation.

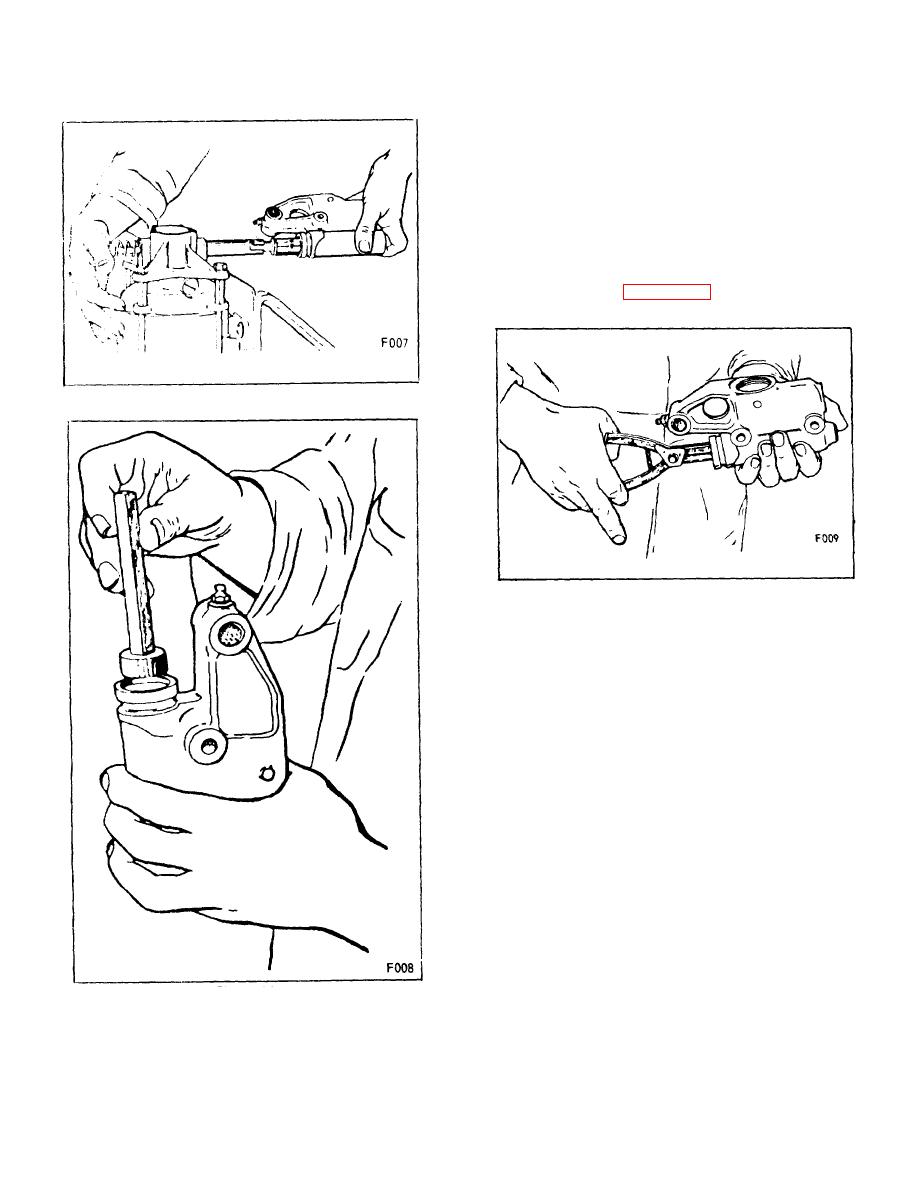

Figure 12 illustrates using a

Wagner de-burring tool.

Figure 10.

Figure 12.

4. Check piston bearing surfaces for scratches or

corrosion and rubber parts for swelling, softening and

tackiness. The spring must be free of corrosion and

pits. Make sure the vent in the filler cap is open.

E. ASSEMBLY

1. Lubricate all parts including the cylinder bore

with brake fluid.

Assemble parts in the opposite

sequence of disassembly, makeing sure the lip of the

primary cup is toward the fitting end of the cylinder. Be

certain the lock wire is firmly seated in the master

cylinder groove.

2. After cylinder has been assembled, purge with

clean hydraulic brake fluid. To purge cylinder: Fill the

reservoir with fluid.

Figure 11.

B-134

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |