|

|||

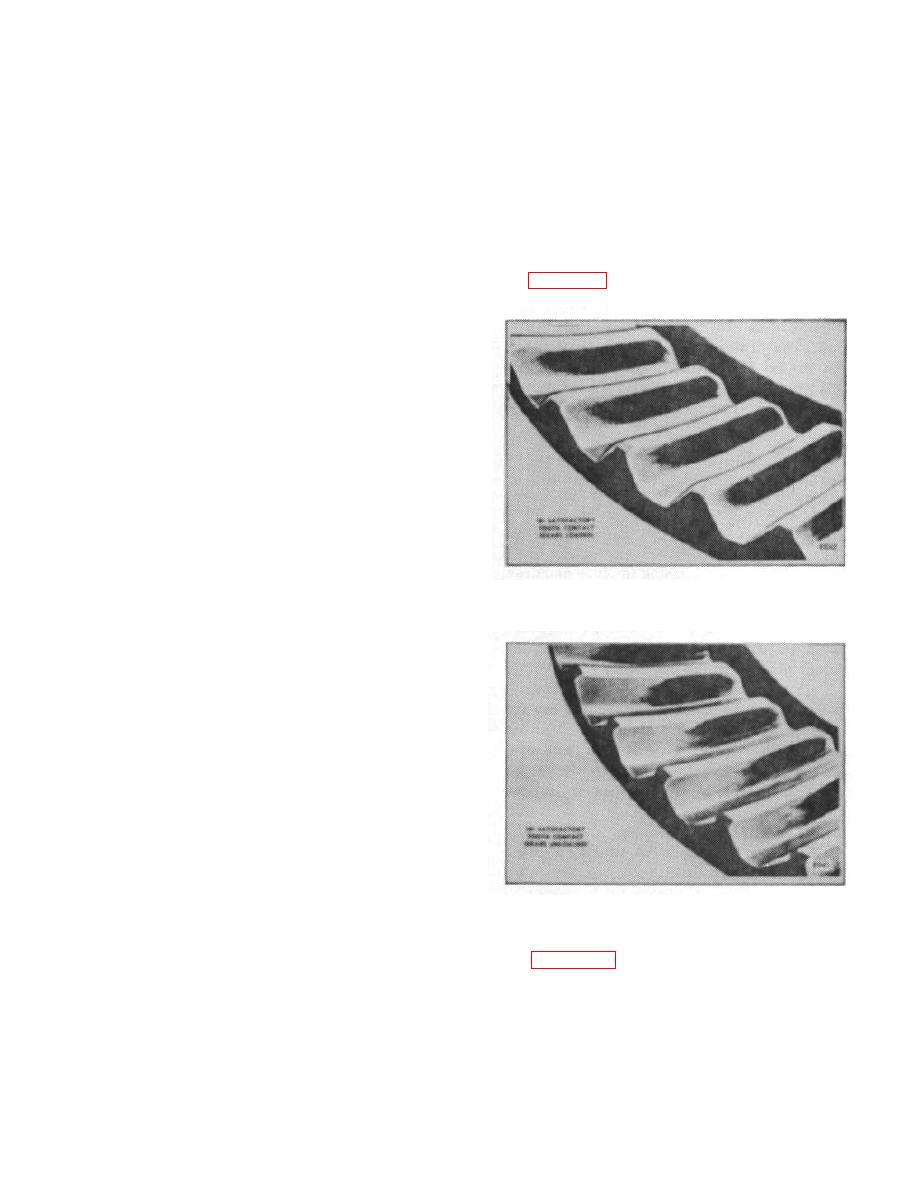

|

|

|||

|

|

|||

| ||||||||||

|

|

DRIVE AXLE

addition of shims between the

4. If backlash is not between .008 and .011 inch,

transmission

and

differential

adjust as necessary.

mounting flanges.

Reference to

moving gear toward or away from

NOTE:

pinion refers to transferring 'shims

To decrease backlash, remove shims

between the R and L axle flanges.

from between the pinion side of the

differential housing and the axle

1. Check adjustments at drive side of bevel gear

housing flange, and place them on

tooth.

the ring gear side.

To increase

clearance, remove the shims from

2. Figures 18 and 19 show correct tooth contact.

the ring gear side of the housing and

place them on the pinion side.

CAUTION:

It is important to place the shims

removed from one side of the

housing on the opposite side.

Otherwise the bearing preload will be

affected.

5. Rotate ring gear and check backlash at several

points on the ring gear. Separate drive axle from the

transmission when the backlash is within specifications.

6. Apply a light coating of white lead to several of

the pinion teeth, on both the drive and coast sides.

Figure 18.

Secure the differential assembly to the transmission

case using new gaskets with the same thickness as the

old gaskets. Tighten down four capscrews spaced

evenly around the flange and rotate the pinion shaft one

full turn in both directions. At the same time, note the

amount of backlash between the ring gear and pinion.

Remove the capscrews and lift the differential assembly

from the transmission.

7. Compare the pattern with those shown in

paragraph D. Tooth Contact.

D. TOOTH CONTACT

NOTE:

The following figures show the

results of too little or too much

pinion depth as determined from the

Figure 19.

impression of the tooth bearing on

the white lead.

3. Figure 20 shows short contact at heel. To

correct, move gear toward pinion. Then move pinion

NOTE:

away from gear to again secure correct backlash.

Reference to moving pinion toward

or away from ring gear in above

description refers to the removal or

B-126

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |