|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ELECTRICAL

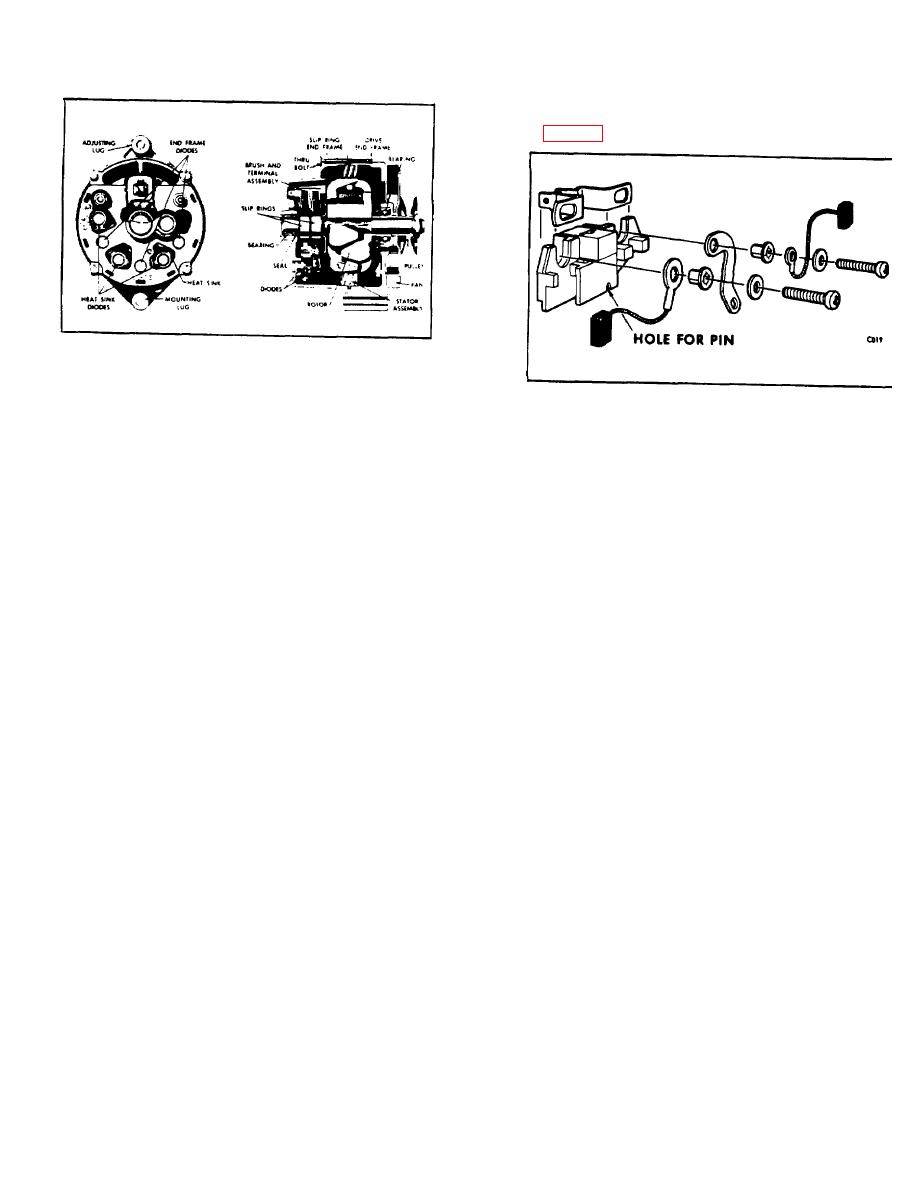

9. Remove the brush holder assembly from the end

frame by detaching the two brush holder assembly

screws. (Fig. 10)

Figure 9.

NOTE: The fit between the stator and

Figure 10.

frame is not tight, and the two can be

separated easily.

Note that the

10. Remove the heat sink by removing the "BAT"

separation is to be made between the

and "GRD" terminals from the end frame, and the screw

stator and drive end frame.

attaching the condenser lead to the heat sink.

3. Tape the slip ring end frame bearing to prevent

D. CLEANING ANO SERVICING

the entry of foreign materials. Tape the shaft on the slip

ring end.

1. Clean the drive end frame bearing in solvent.

4. Place the rotor in a soft-jawed vise. Tighten the

2. Inspect the bearing. If it is in satisfactory

vise only enough to enable removal of the shaft nut.

condition, it may be re-used, and should be filled one-

Unscrew the shaft nut. Remove the pulley, fan and

quarter full with proper lubricant before reassembly.

collar.

CAUTION: Do not overfill, as this may cause the

5. Separate the drive end frame from the rotor.

bearing to overheat.

6. Remove the diodes only when necessary. To

3. When the slip ring end frame assembly is

remove a diode, support the end frame or heat sink on

separated from the rotor and drive end frame assembly,

an arbor press and push the diode out.

the brushed will fall down onto the shaft and come in

contact with the lubricant. If the brushes are to be re-

CAUTION: Do not strike the diode, as the shock may

used, they must be thoroughly cleaned with a soft dry

cause damage.

cloth. Also, the shaft must be thoroughly cleaned before

reassembly.

7. Remove the drive end bearing retainer and press

the bearing from the drive end.

4. The brush springs should be inspected for any

evidence of damage or corrosion. If there is any doubt

8. Remove the bearing from the slip ring end frame

as to the condition of the brush springs, they should be

only when necessary. To remove the bearing, press out

replaced.

with a tube or collar that just fits inside the end frame

housing. Press from the outside of the housing towards

the inside.

B-60

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |