|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

FUEL

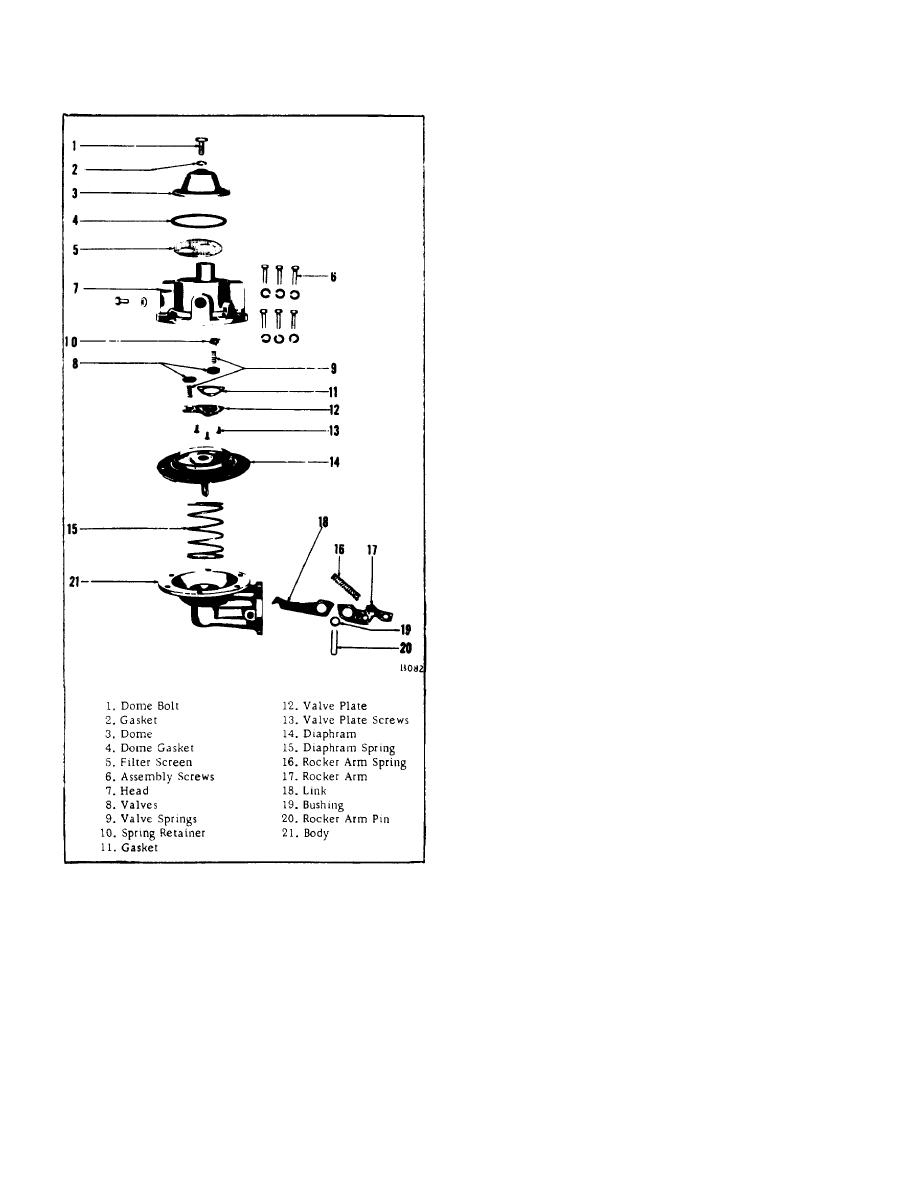

1. File match marks across a point at the union of

the head (7) and body (21). Unscrew the assembly

screws (6) and remove the head (7).

2. Unscrew the dome bolt. Remove the dome (3),

dome gasket (4) and filter screen (5).

3. Unscrew the three valve plate screws (13). Lift

out the valve plate (12), plate gasket (11), valves (8),

valve springs (9) and the valve spring retainer (10).

4. Pry the' rocker arm spring (16) out of position,

using a screw driver inserted-in the coils of the spring.

5. With the heel of the hand on the diaphragm

(14), compress the diaphragm spring (15) and unhook

the diaphragm from the link (18).

6. Drive the rocker arm pin (20) out. Remove

rocker arm (17), linkage (18) and bushing (19).

D. CLEANING AND INSPECTION

1. Clean: all parts with solvent.

NOTE

The following are points where wear affects fuel

pump performance as noted:

a. Worn linkage causes slow priming and

lack of fuel.

b. Worn pull rod causes improper

diaphragm action.

c. Dirty valve seats or worn valves result

in reduced fuel flow.

d. Ruptured diaphragm reduces the fuel

pressure and flow.

2. Visually check the cover and body for cracks

and breakage. Inspect for diaphragm flange warpage by

testing on a smooth flat surface. Examine all threaded

holes for stripped or crossed threads. Broken, damaged

or severely warped castings must be replaced.

3. Replace valves if obviously worn or damaged.

Figure 6.

B-44

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |