|

|||

|

|

|||

|

Page Title:

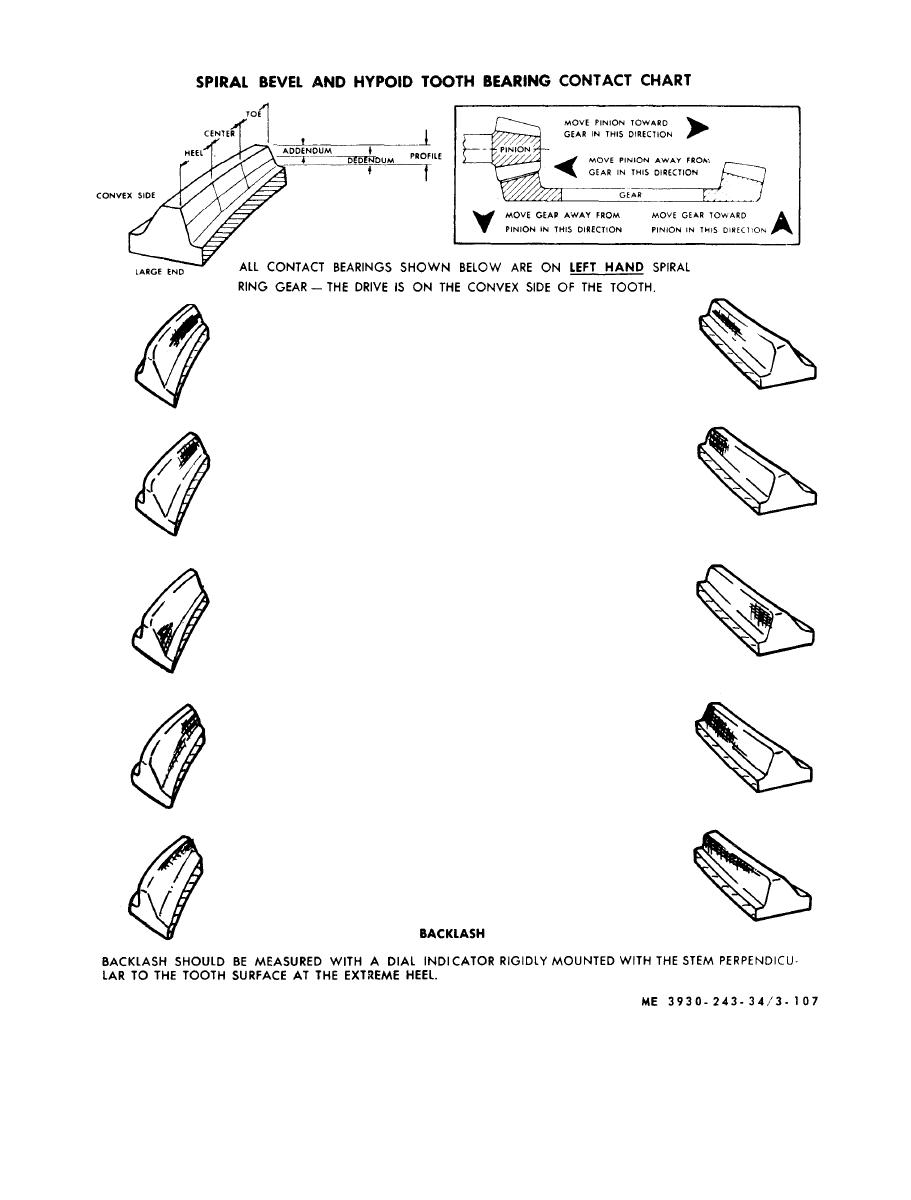

Figure 3-107. Correct tooth contact patterns. |

|

||

| ||||||||||

|

|

FIG. 1

TYPICAL PREFERRED BEARING ON BOTH SIDES OF TOOTH

WHILE UNDER A LIGHT LOAD

FIG. 2

TOE BEARING ON BOTH SIDES OF TOOTH - GEAR SET NOISY. TO MOVE

BEARING TOWARD HEEL INCREASE BACKLASH WITHIN LIMITS BY MOV-

ING GEAR AWAY FROM PINION.

FIG. 3

HEEL BEARING ON BOTH SIDES OF TOOTH-GEARSET NOISY AND

COULD RESULT IN EARLY GEAR FAILURE. TO MOVE BEARING TOWARD

TOE DECREASE BACKLASH WITHIN LIMITS BY MOVING GEAR TOWARD

PINION.

FIG. 4

LOW BEARING ON GEAR AND HIGH BEARING ON PINION. CORRECT

BY PULLING PINION AWAY FROM GEAR (INCREASE MOUNTING DIS-

TANCE.

FIG. 5

HIGH BEARING ON GEAR AND LOW BEARING ON PINION. CORRECT

BY MOVING PINION IN TOWARD GEAR (DECREASE MOUNTING DIS-

TANCE.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |