|

|||

|

|

|||

|

Page Title:

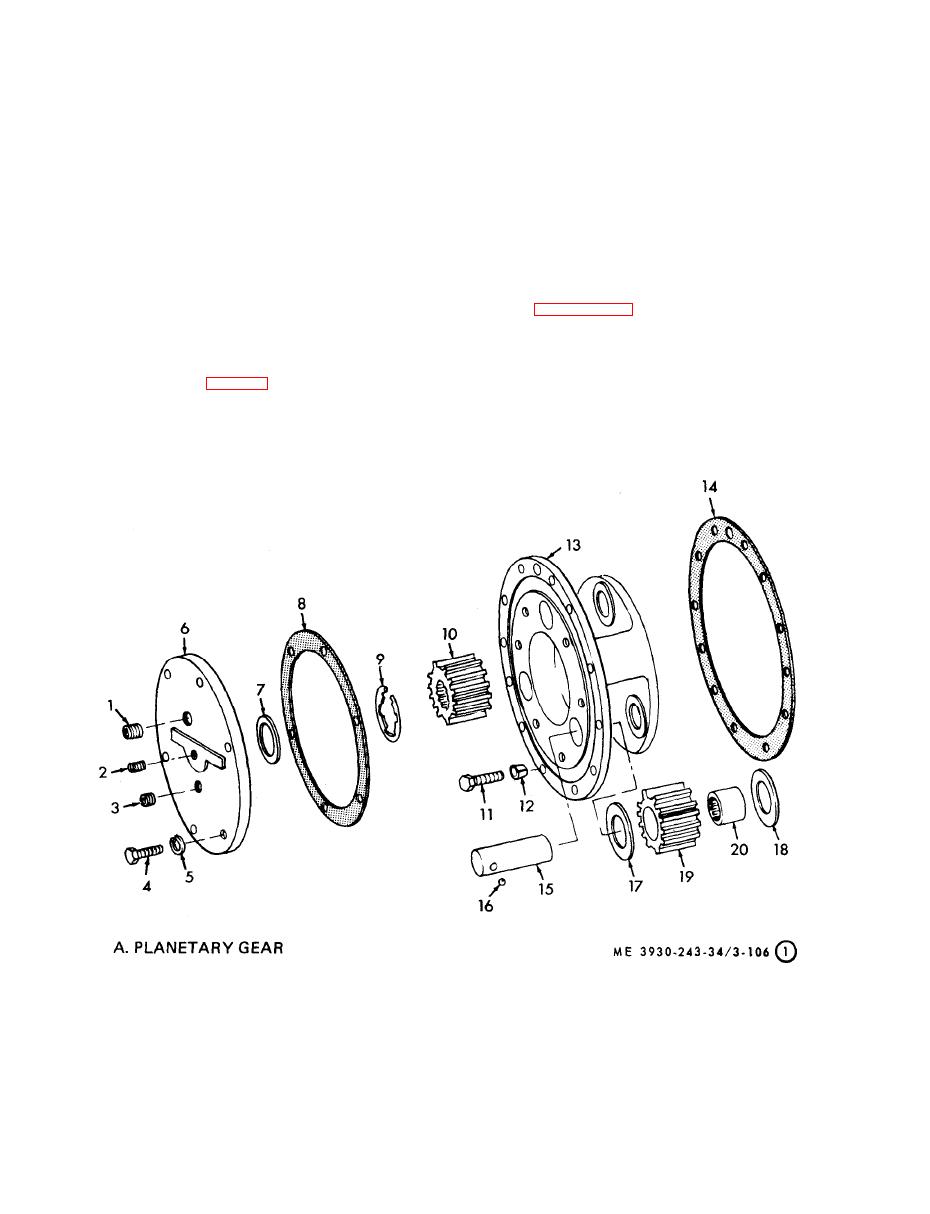

Figure 3-106. Axle assembly, disassembly and reassembly (sheet 1 of 6). |

|

||

| ||||||||||

|

|

half case solidly to seat bearings. Back off nuts on

(d) Tap plain differential case (97) into

made during

marks

place, a l i g n i n g p u n c h

flange side, one notch at a time and follow with

disassembly. Install screw (95) and nuts (96).

opposite nut until correct backlash is obtained.

Tighten to correct torque.

(b) If backlash is under minimum

(4) Assemble the differential pinion and

specification, back off nut on flange half and

bearing (64 thru 92) as follows:

t i g h t e n nut on opposite side. Operation should be

done in one notch steps until correct backlash is

(a) Press pilot bearing (84) on drive pinion

(83), then stake in four places.

obtained.

(b) Press bearing cone (79) on pinion.

(c) T i g h t e n c a r r i e r c a p b o l t s t o s p e c i f i e d

Lubricate bearing.

t o r q u e . Recheck backlash. If backlash is not within

limits repeat above procedure to correct. Install

(c) P r e s s b e a r i n g c u p ( 7 2 ) i n t o p i n i o n

b e a r i n g case (73). Install new gasket (72) and oil

b e a r i n g adjusting nut locks and secure with screw

seal (71) in oil seal retainer (70).

and lockwasher; lockwire to prevent loosening.

Refer to figure 3-107 for correct tooth contact.

(d) I n s t a l l y o k e a s s e m b l y ( 6 7 ) .

(7) Install carrier housing (92) to axle housing

(5) Reassemble differential assembly in carrier

(124).

( 9 2 ) . Insure that punch marks on carrier leg (92)

( 8 ) Reassemble axle assembly in reverse order

a n d cap (91) are aligned for proper fit. Tighten to

of disassembly.

specified torque (para 1-4).

(6) Adjust backlash 0.006 to 0.016 as follows:

NOTE

Torque all bolts to specified torque as shown in

(a) If backlash is too great, back off ad-

j u s t i n g nut on plain half case and tighten opposite

s i d e until all lash is removed. Tighten nut on plain

16

Ball

11

Screw

6

End cover

1

Plug

17

Washer

12

Bushing

7

Washer

2

Plug

18

Washer

8

Gasket

13

Planetary case

3

Plug

19

Gear

9

Ring

14

Gasket

4

Screw

20

Needle bearing

15

Pin

10

Sun gear

5

Lockwasher

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |