|

|||

|

|

|||

|

Page Title:

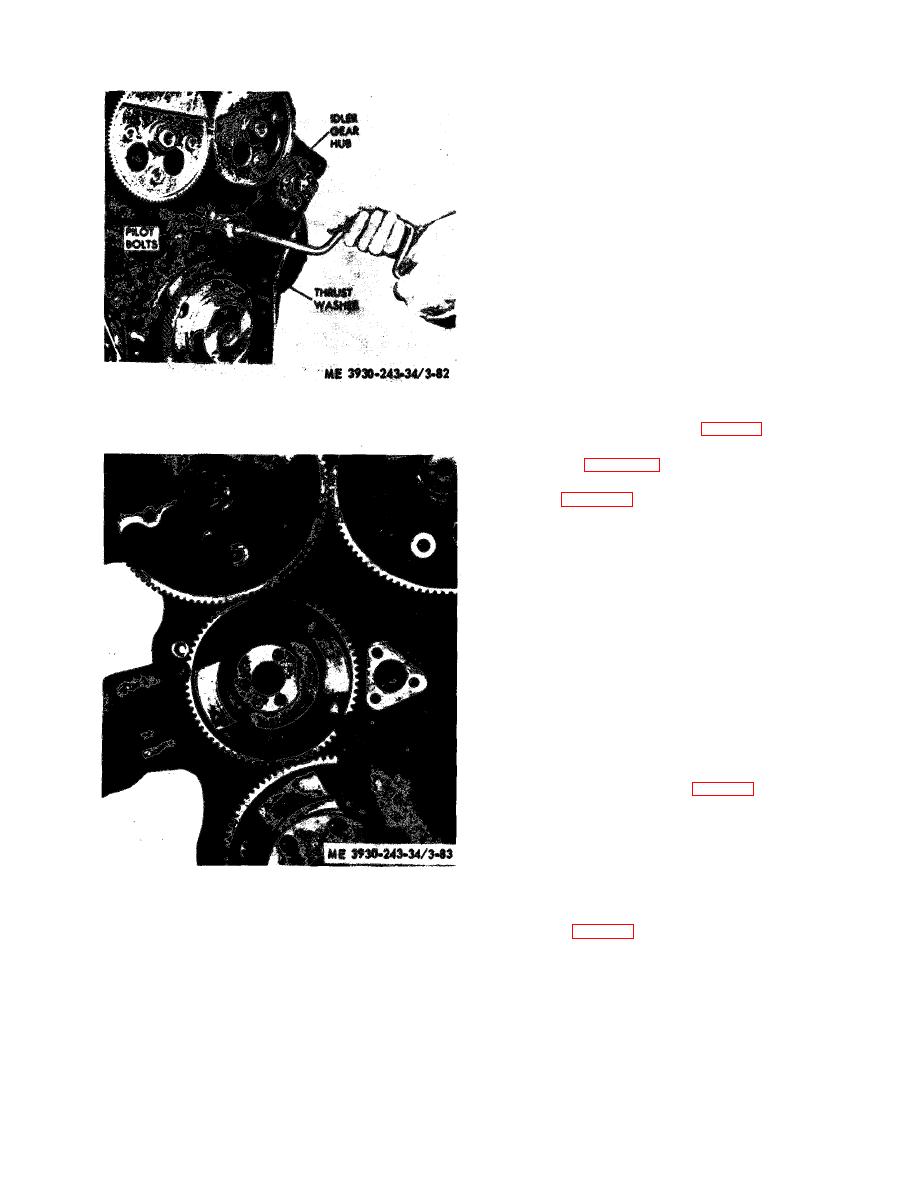

Figure 3-82. Installing idler gear hub. |

|

||

| ||||||||||

|

|

consist of an upper shell seated in cylinder Mock

main bearing support and a lower shell seated in

main bearing cap. The bearings are numbered 1, 2,

3 , etc., indicating their respective position, and

when removed must always be reinstalled in their

original position. Lower main bearing shells have

no grooves; therefore, the upper and lower bearing

shells must not be interchanged. An oil hole in the

groove of each upper shell midway between the

parting liner registers with a vertical oil passage in

the cylinder block. Lubricating oil, under pressure

p a s s e s from the cylinder block by way of the

bearing shell to the drilled passages in the

crankshaft then to the connecting rods. Rear main

bearing thrust washers absorb the crankshaft thrust

at each side of the rear main bearing. Each washer

is made of two halves; the lower halves are doweled

to the bearing cap, the upper halves are not

doweled.

b. Removal (crankshaft in place).

(1) Remove the engine (para 2-9).

(2) Remove the oil pan to expose the main

bearing caps (para 3-24).

(3) Remove the oil pump inlet pipe and screen

assembly (para 3-25).

(4) Remove all except the rear main bearing,

dress down the head of a 1/4" x 3/4" bolt to a

thickness of 1/16". (The thickness of the dressed

down bolt head, must be less than the thickness of

the bearing shell.) Insert the bolt into the

crankshaft journal oil hole and revolve the

c r a n k s h a f t so that the bolt head contacts the

bearing shell opposite the bearing locating tang and

roll the bearing out of the block.

NOTE

Remove one main bearing cap at a time, inspect as

outlined under INSPECTION in this section, and

complete replacement of shell and reinstallation of

cap before another cap is removed.

(5) Two-piece thrust washers are used on each

side of the rear main bearing (fig. 3-84). The lower

h a l f of these washers will be removed when

r e m o v i n g the rear main bearing cap; upper half

can be removed by pushing on end of washer with a

small rod, thus forcing washer around and out on

opposite side of bearing.

(6) Remove rear main bearing upper shell by

driving on the edge of the bearing shell with a small

curved rod (fig. 3-85), at the same time revolving

a. General. The main bearing shells are of

t h e crankshaft, thus rolling the shell from its

precision type and are readily replaceable without

position.

m a c h i n i n g . They are used at each journal and

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |