|

|||

|

|

|||

|

Page Title:

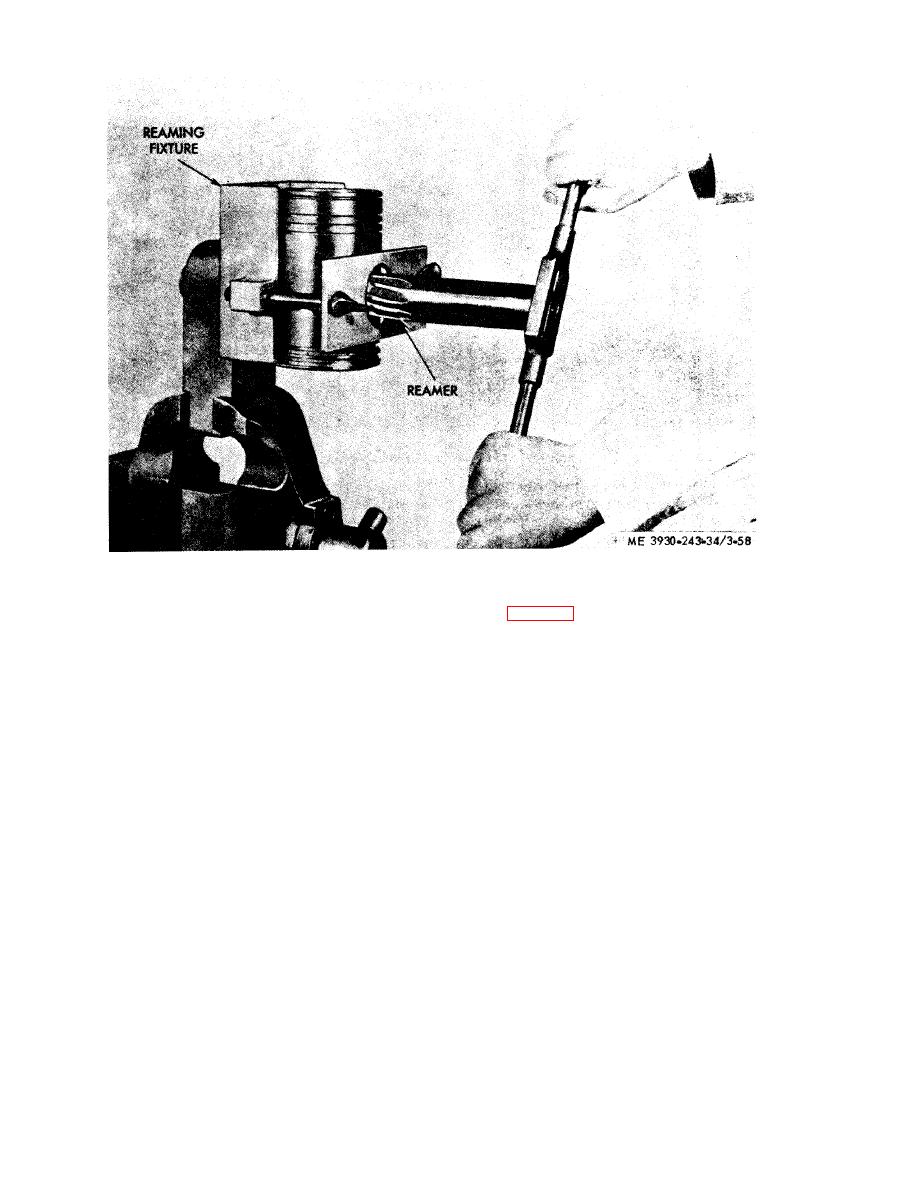

Figure 3-58. Reaming bushing in piston. |

|

||

| ||||||||||

|

|

liner (fig. 3-59), then withdraw feeler ribbon,

(h) The piston taper must not exceed 0.0005

measuring the force required with a spring scale.

inch from 7/16 inch below the bottom com-

This force should not exceed six pounds. When this

pression ring to the lower end of piston skirt. The

force is approximately 6 pounds, the actual

d i a m e t e r of a new standard piston below the

clearance between the piston and the liner is 0.001

compression ring grooves to bottom of piston skirt

inch greater than the thickness of the feeler ribbon

is 3.8693 to 3.8715 inch.

(i) Check the piston-to-liner clearance while

used. Feeler ribbon used for checking this clearance

the piston is held upside down in the liner. The liner

must be perfectly flat and free from nicks and

should be in place in the cylinder block. This

scratches.

NOTE

clearance should always be checked when installing

If any bind between the piston and liner is detected,

either new or used pistons and liners. The clearance

remove the piston and liner and inspect them for

of a piston in a liner may be checked with liner in

burs. If either part is marred, the parts must be

cylinder block, by inserting a inch wide feeler

cleaned up, using a fine hone on the liner and fine file

ribbon about 15 inches long between the piston and

on the piston before proceeding.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |