|

|||

|

|

|||

|

Page Title:

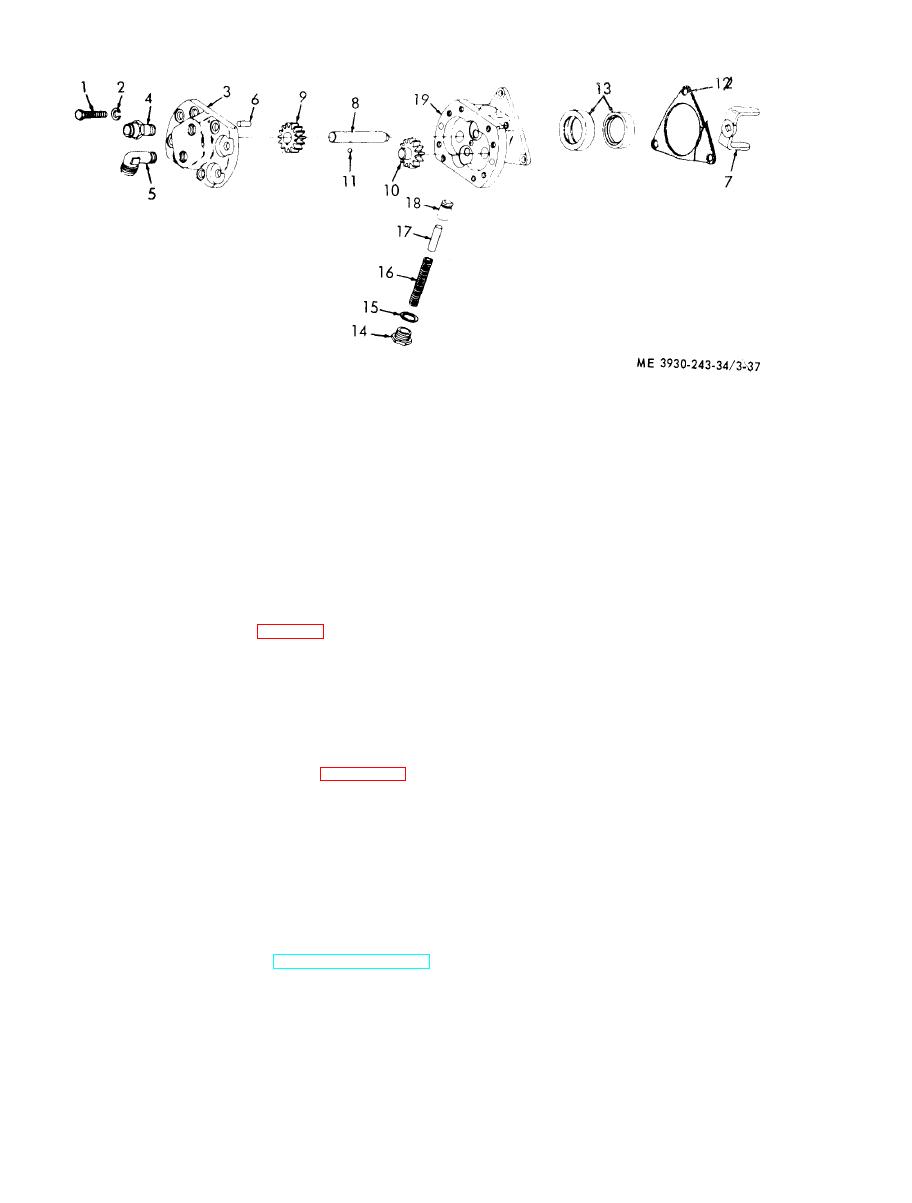

Figure 3-37. Fuel pump, disassembly and reassembly. |

|

||

| ||||||||||

|

|

11

Gear retaining ball

1

Screw

12

Gasket

2

Lockwasher

13

Oil seals

3

Pump cover

14

Valve plug

4

Adapter

15

Gasket

5

Elbow

16

Spring

Dowel pin

6

7

17

Pin

Coupling drive fork

18

Relief valve

8 Drive shaft

19

Pump body

9 Drive gear

10 Driven gear and shaft

side of the forklift opposite the driver's seat. The

f. Inspection.

fuel tank is made from a heavy guage metal and

(1) Remove and discard the oil seals. Inspect

access steps are made on the fuel tank.

the pump drive shaft (8, fig. 3-37) for nicks and

b. Removal. R e m o v e t h e f u e l t a n k ( T M 1 0 -

scratches. Remove scratches with crocus cloth.

3930-243-12).

(2) Inspect the gear teeth (9 and 10) for

c. Testing. Install pipe plugs in all openings of

scoring or chipping.

t h e tank except one. In the remaining opening,

( 3 ) Inspect the mating faces of the housing

install a source of air pressure. Submerge the tank

(19) and cover (3) for tight fit.

in water and apply approximately 15 psi of air. If

(4) Inspect the relief valve (18) for score

marks and proper fitting into seat of pump housing.

air bubbles appear, they denote a leak. Repair, or

replace the fuel tank if damaged beyond repair.

g. Reassembly. Refer to figure 3-37 and

After repair, retest the fuel tank.

reassemble the fuel pump assembly. Reassembly

WARNING

is the reverse procedure of disassembly.

B e f o r e attempting to weld or braze the

NOTE

fuel tank, steam clean the tank for a

After assembly rotate the pump shaft by hand to

minimum of eight (8) hours. Remove

make certain that the parts rotate freely. When the

fuel cap and open the discharge and

shaft does not rotate freely, attempt to free it by

return lines during the welding process.

tapping a corner of the pump.

Failure to observe this warning may

h. Installation.

r e s u l t in serious injury or death.

(1) Remove caps from fuel lines.

d. Installation. I n s t a l l t h e f u e l t a n k ( T M 1 0 -

( 2 ) Install fuel pump (TM 10-3930-243-12).

3930-243-12).

3-17. Fuel Tank

a. General. The fuel tank is located on the right

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |