|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

d i r e c t current voltmeter to the starter terminal and

3-10. S t a r t i n g M o t o r

t h e starter housing. With voltage adjusted to 22.5

a. General. The starter is mounted to the

v o l t s , the current should be 80 amperes maximum

flywheel housing. It is 24 volt DC. The starter

at 3,600 rpm. If current and speed are both low,

components are totally enclosed to protect them

inspect for high resistance in the internal con-

from road dirt, icing conditions and road splash.

nections. If current is high and speed is low, inspect

b. Removal. Remove the starter (TM 10-3930-

the bearings and armature for binding and in-

243-12).

correct alignment.

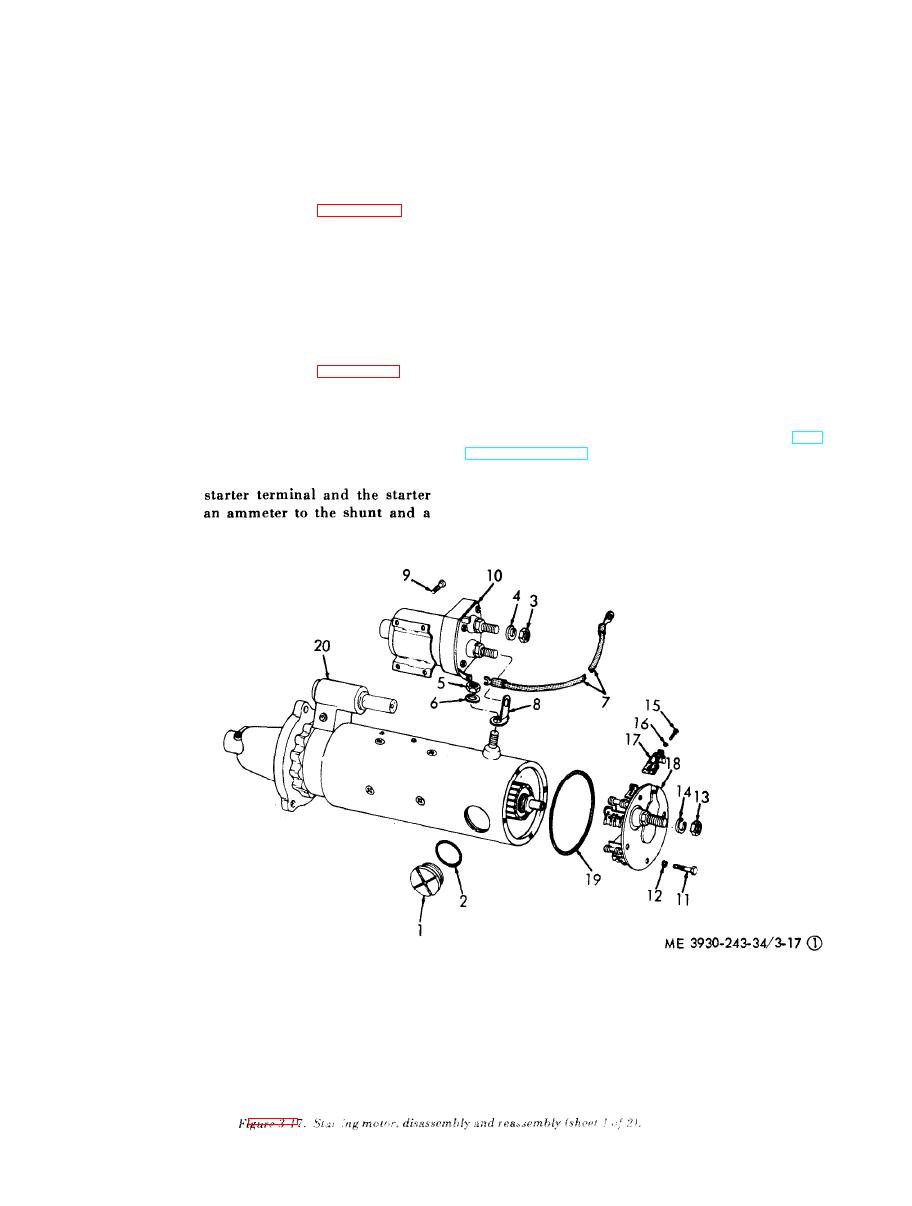

disassemble the starting motor in numerical

n e c t e d as in (1) above, fasten a torque arm and a

sequence.

spring scale to the armature at the drive end. Adjust

d. Inspection.

the rheostat to give 3.52 volts. The correct readings

( 1 ) Inspect field coils, armature and insulating

are 500 amperes and a stall torque of 20 foot-

parts for any damage.

pounds minimum. The stall torque is the product of

(2) Inspect bushing for excessive wear.

the spring scale reading in pounds multiplied by the

(3) Inspect brushes for excessive wear.

torque arm in feet. If the current and torque are

Replace a defective or worn part.

b o t h low, inspect for high resistance in the internal

c o n n e c t i o n s and for improper brush contact. High

reassemble the starting motor. Reassembly is the

current and low torque may be caused by a

reverse procedure of disassembly.

defective armature or field coil.

f. Bench Testing.

g. Installation. Install the starting motor (TM

(1) No load test. Connect a 24 volt battery in

10-3930-243-12).

series with a load rheostat and an ammeter shunt of

h. On-Equipment Testing. Refer to TM 10-

a capacity greater than 50 amperes and connect

3930-243-12 for on-equipment testing procedures.

this group to the

housing. Connect

1 1 Screw

1

Plug

12 Lockwasher

2

Gasket

13

Nut

3

Nut

14

Lockwasher

4

Lockwasher

15

Screw

5

Nut

16

Lockwasher

6

Lockwasher

17

Brush

7

Lead

18

End bell

8

Connector

19

Packing

9

Screw

10

20

Starter assembly

(1) Starter and brushes

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |