|

|||

|

|

|||

|

Page Title:

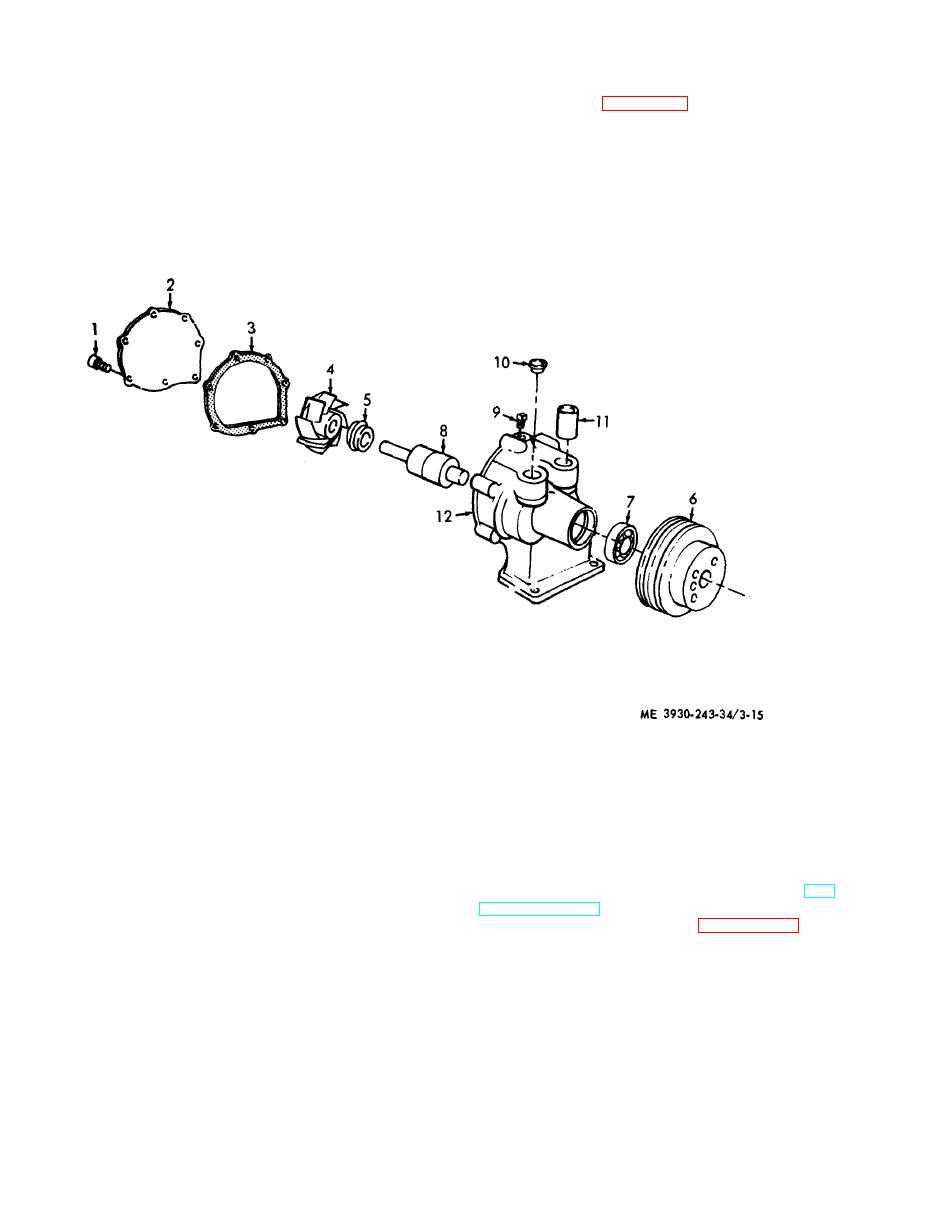

Figure 3-15. Water pump, disassembly and reassembly. |

|

||

| ||||||||||

|

|

e. Reassembly.

d. Inspection.

(1) Refer to figure 3-15 and reassemble the

(1) Inspect the impeller for damage or ex-

water pump in reverse order of disassembly.

cessive wear on impeller face which contacts the

(2) Run the pump dry at 1200 rpm for 30

seal.

seconds to assure seating of the seal.

(2) Revolve the shaft bearings slowly by hand;

if rough or tight spots are detected, the bearing and

shaft must be replaced.

7

Bearing

1

Screw

8

Shaft

2

Cover

9

Plug

3

Gasket

10

Plug

4

Impeller

11

Nipple

5

Seal

12

Body

6

Pulley

f. Installation. Install the water pump (TM 10-

10-3930-243-12).

3930-243-12).

disassemble the engine generator.

d. Inspection.

DC generator. The battery charging generator is

(1) Inspect insulation, leads and windings.

introduced into the electrical system to provide a

( 2 ) Inspect commutator bars for roughness

s o u r c e of electrical current for maintaining the

and pitting.

s t o r a g e battery in a charged condition and to

(3) Inspect all bearings for excessive wear.

supply sufficient current to carry any other elec-

(4) I n s p e c t brushes for wear. Replace a

trical load requirements up to the rated capacity of

missing or defective part.

the generator.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |