|

|||

|

|

|||

|

Page Title:

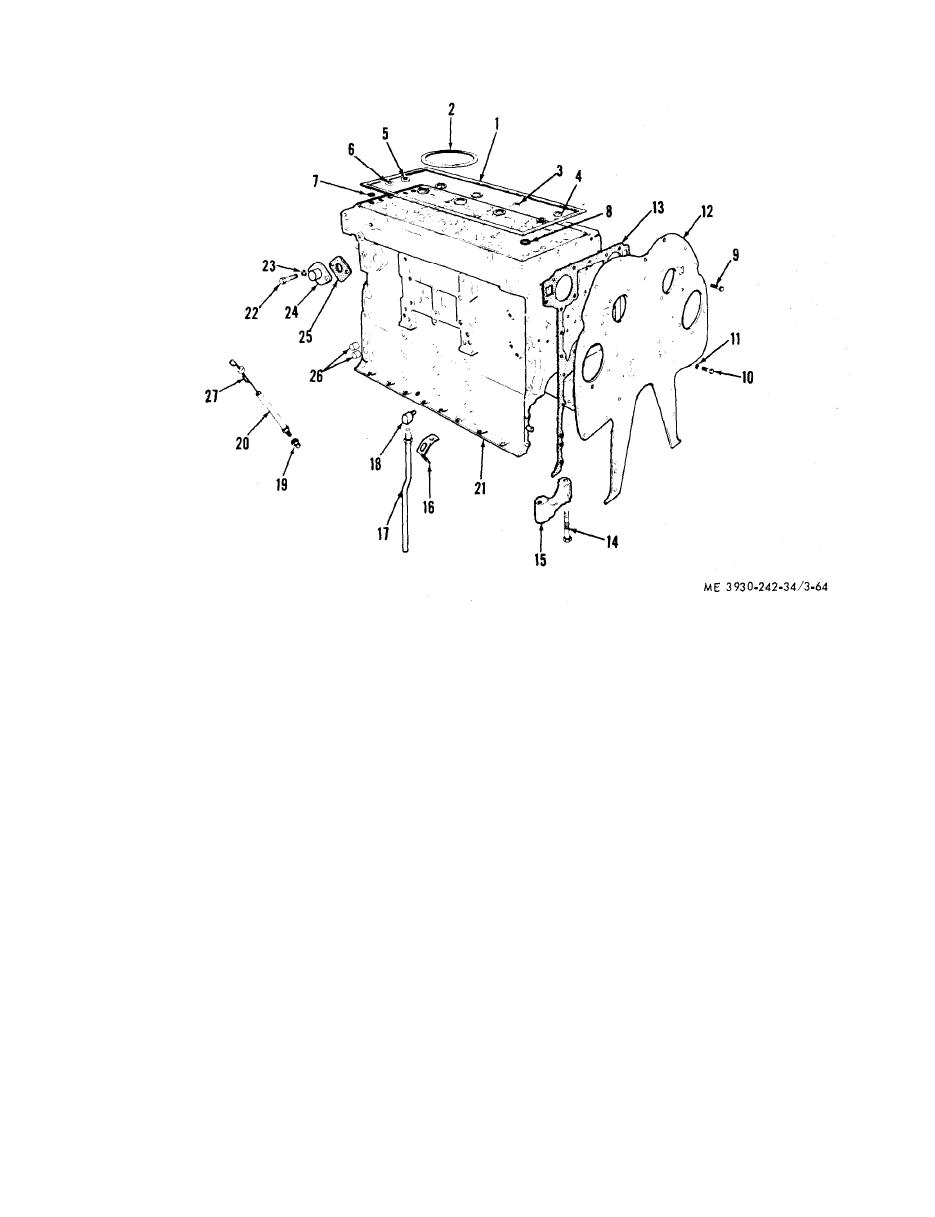

Figure 3-64. Cylinder block, disassembly and reassembly. |

|

||

| ||||||||||

|

|

TM 10-3930-242-34

10

Screw

1

Gasket

19

Nut

11

Washer

2

Ring

20

Guide

12

Plate

3

Ring

21

Block

13

Gasket

4

Ring

22

Screw

14

Capscrew

5

Ring

23

Lockwasher

15

Cap

6

Ring

24

Cover

16

Clip

7

Ring

25

Gasket

17

Tube assembly

8

Ring

26

Plug

18

Elbow

9

Screw

27

Dipstick

and suitable rubber gaskets held in place by

f o o t - p o u n d s torque. Caps are numbered to cor-

bolts.

r e s p o n d with their respective positions in the

(e) Immerse the cylinder block for 20 mi-

b l o c k . The number of the front and rear main

nutes in a tank of water heated to 180-200 F.

b e a r i n g caps is stamped on the face of the oil

(f) Using a suitable fitting at one of the

pan mounting flange of the cylinder block, adja-

w a t e r inlet or outlet openings, apply 15 pounds

c e n t to their permanent location in the engine,

a s established at the time of manufacture. The

per square inch air pressure to water jacket and

observe water in the tank for bubbles indicating

number 1 cylinder and main bearing cap are

cracks or leaks.

a l w a y s located at the end opposite the flywheel

(g) Following the pressure test, blow out

e n d of the cylinder block, regardless of engine

p a s s a g e s with dry compressed air.

r o t a t i o n . The standard bearing bore diameter is

( 3 ) Inspect cylinder block. A f t e r c l e a n i n g

3.251-3.353 inches.

a n d pressure testing the cylinder block should

(b) Check the cylinder liner counterborek

be inspected as follows:

for squareness, proper depth, and diameter.

(a) Check the main bearing bores. Check

C o u n t e r b o r e s should be from 4.825-4.835 inches

b o r e inside diameter with main bearing caps

in diameter. Counterbored surfaces must be

secured in place with bolts tightened to 120-130

smooth and square with the cylinder bore

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |