|

|||

|

|

|||

|

Page Title:

Fitting cylinder liner to bore in block: |

|

||

| ||||||||||

|

|

TM 10-3930-242-34

3. Clamp the liner in place with a hold-

ceeds 0.003 inch, replace the liner. To check the

d o w n clamp and measure distance from top of

d i m e n s i o n s , use a dial bore gage which has a

the liner flange to top of the block. The top of the

d i a l indicator calibrated in 0,0001 inch incre-

ments.

l i n e r flange should be 0.0465-0.050 inch below

t o p of the block; and there must not be over

CAUTION

0.0015 inch difference between any two adjacent

Do not drop or slam liner against the bot-

l i n e r s when measured along the cylinder lon-

tom of counterbore in the block.

gitudinal centerline. If above limits are not met,

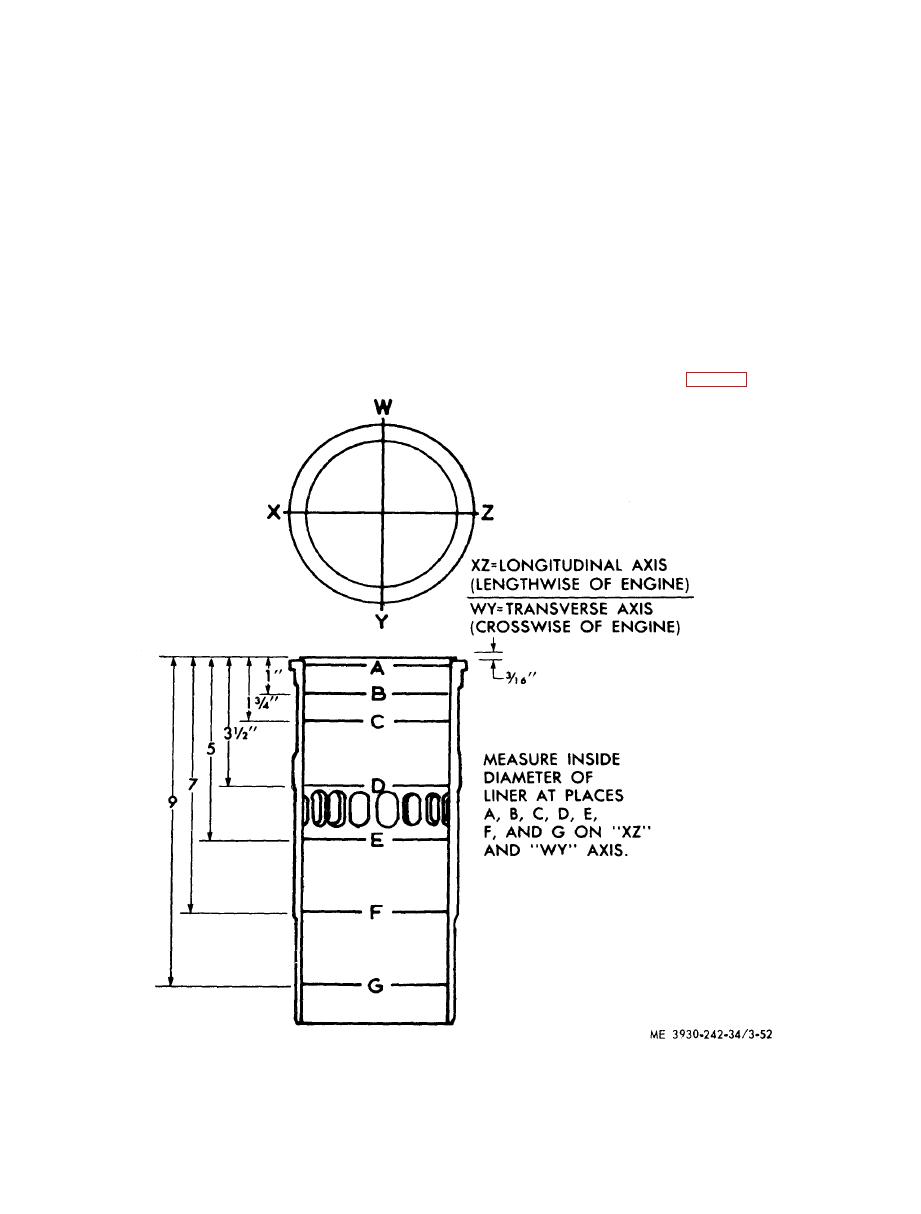

(d) Fitting cylinder liner to bore in block:

install liner in another bore, and recheck, or use

1. Clean inside and outside of cylinder

a new liner.

liner. Also, clean block bore and counterbore to

4. Match mark the liner and block with

i n s u r e proper seating. Then, slide the liner into

c h a l k or paint on the seral number side of en-

b l o c k until flange on liner rests on bottom of

g i n e to insure the liner is reinstalled in same

c o u n t e r b o r e in the block.

position in the same bore.

2. T a p t h e l i n e r l i g h t l y w i t h a s o f t

5. Remove holddown clamp and liner.

h a m m e r to make certain the liner flange seats

e. Reassembly.

o n bottom of counterbore.

(1) With the piston (13, fig. 3-51) assembled

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |