|

|||

|

|

|||

|

Page Title:

Section III. CYLINDER HEAD, VALVES, FLYWHEEL, AND FLYWHEEL HOUSING |

|

||

| ||||||||||

|

|

TM 10-3930-242-34

Section III. CYLINDER HEAD, VALVES, FLYWHEEL,

AND FLYWHEEL HOUSING

3 - 1 8 . General

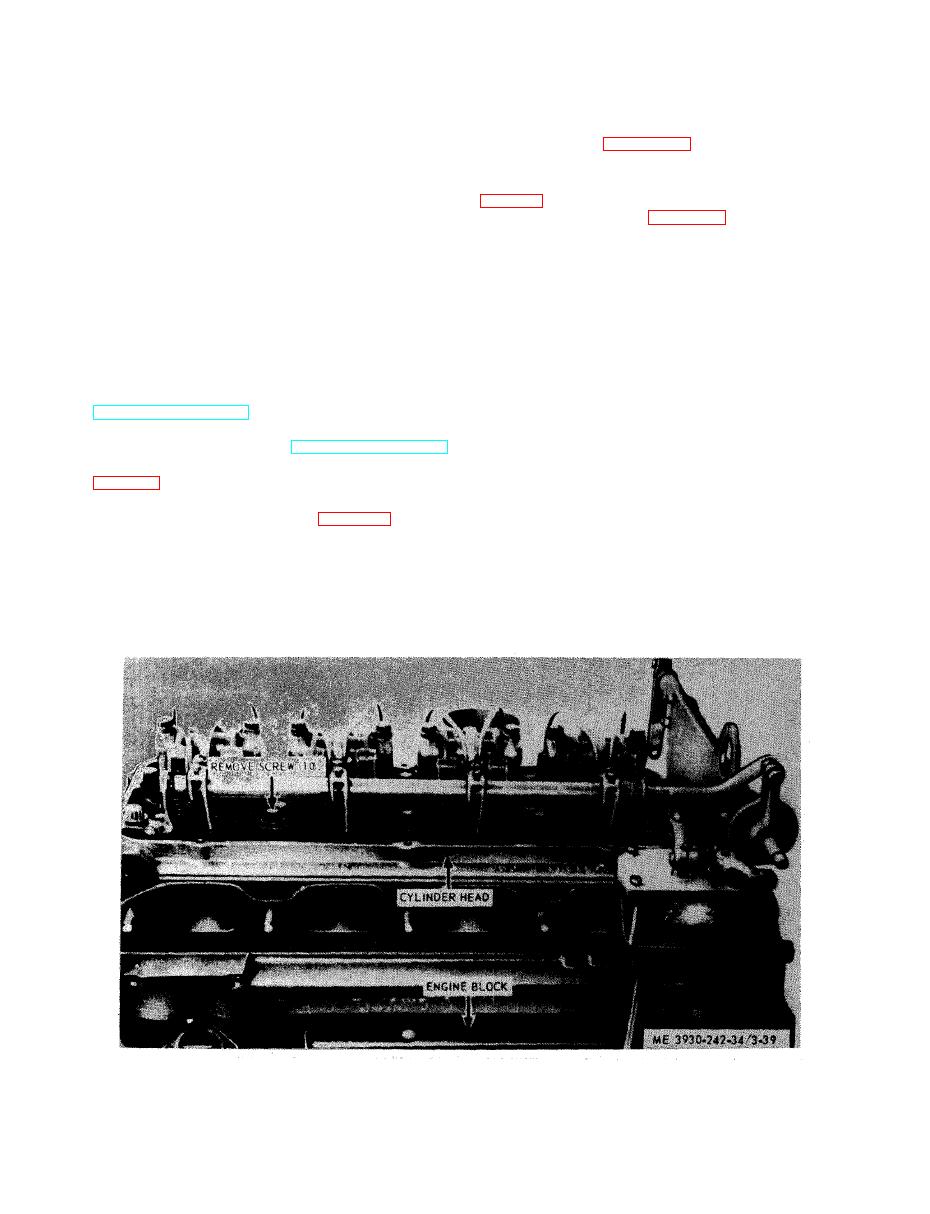

(5) Refer to figure 3-39 and remove cylinder

h e a d assembly.

This section contains maintenance informa-

( 6 ) Remove exhaust valve and valve spring

t i o n on those items that are considered compo-

(para 3-20).-

nents of the engine. These items consist of vari-

o u s parts which make up the basic engine.

a s s e m b l e cylinder head.

3-19. Cylinder Head and Valves

d. Cleaning and Inspection.

a. General. The cylinder head is a one piece

(1) Clean cylinder head. After the cylinder

c a s t i n g mounted to cylinder block. The cylinder

head has been stripped of all parts, it should be

head serves as the removable access point to the

thoroughly steam cleaned. Thoroughly clean a

u p p e r engine components and as a mounting

s e r v i c e cylinder head to remove all of the rust

m e m b e r for the valves, fuel injectors, and the

p r o o f i n g compound, particularly from the in-

exhaust manifold.

t e g r a l fuel manifolds, before the plugs are. in-

b. Removal.

s t a l l e d in the fuel manifolds and the head is

(1) Drain cooling system and engine block

m o u n t e d on an engine. A simple method of re-

(TM 10-3930-242-12).

moving the rust proofing compound is to im-

(2) Remove thermostat, thermostat hous-

m e r s e the head in solvent, oleum or fuel oil;

ing, and exhaust manifold (TM 10-3930-242-12).

then go over the head and through all openings

(3) Remove rocker arms and push rods

w i t h a soft bristled brush. After cleaning the

h e a d , it should be blown dry with compressed

t w e e n governor and injector control tube lever.

air to remove all of the solvent.

(4) Remove fuel injectors (para 3-14).

(2) Inspect cylinder head. Over a prolonged

p e r i o d of operation, the cylinder head may as-

CAUTION

sume a contour to match that the cylinder block,

When resting cylinder head assembly on

w h i c h is normal. However, if the cylinder head

work bench, protect cam follower rollers

is allowed to become overheated because of

and injector spray tips by resting valve

c o o l a n t loss, the resultant high temperatures

side of head on wooden blocks at least 2

cause stresses to occur in the casting which will

inches thick.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |