|

|||

|

|

|||

|

Page Title:

Section XIII. MAINTENANCE OF PROPELLER SHAFT |

|

||

| ||||||||||

|

|

TM10-3930-242-12

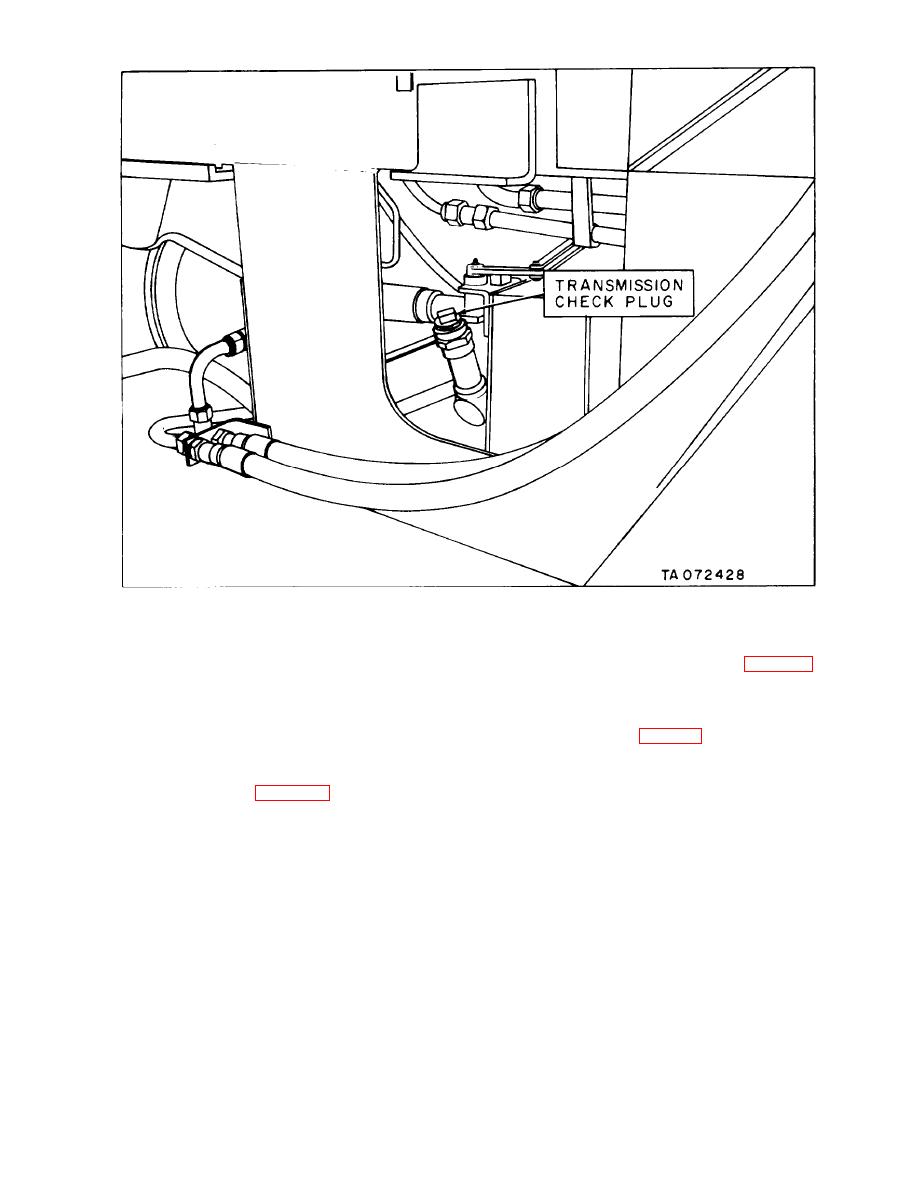

(1) Range Selector Linkage (low, med, high).

NOTE

Make sure operator's controls (fig. 2-1) are

Refer to current lubrication order for

positioned to correspond exactly with the detent

maintenance instructions for internal oil

positions of range selector valve.

filter screen.

(2) Forward and Reverse Linkage. Make sure

operator's controls (fig. 2-1) correspond exactly

with valve selector detents.

a. Inspect. Check all linkage between operator's

b. Repair. If (1) or (2) above are out of adjustment

controls and transmission frequently. Remove

or need repair, report to direct support maintenance.

console panel cover (fig. 4-31) and inspect the

linkage for proper lubrication, cleanliness, wear, and

damage.

Section XIII. MAINTENANCE OF PROPELLER SHAFT

WARNING

Drycleaning solvent, P-D-680, used to

clean parts is potentially dangerous to

flange for cracks, breaks, broken welds, or other

personnel and property. Do not use near

damage.

open flame or excessive heat. Flash point

of solvent is 138F.

flanges in accordance with current lubrication order.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |