|

|||

|

|

|||

|

Page Title:

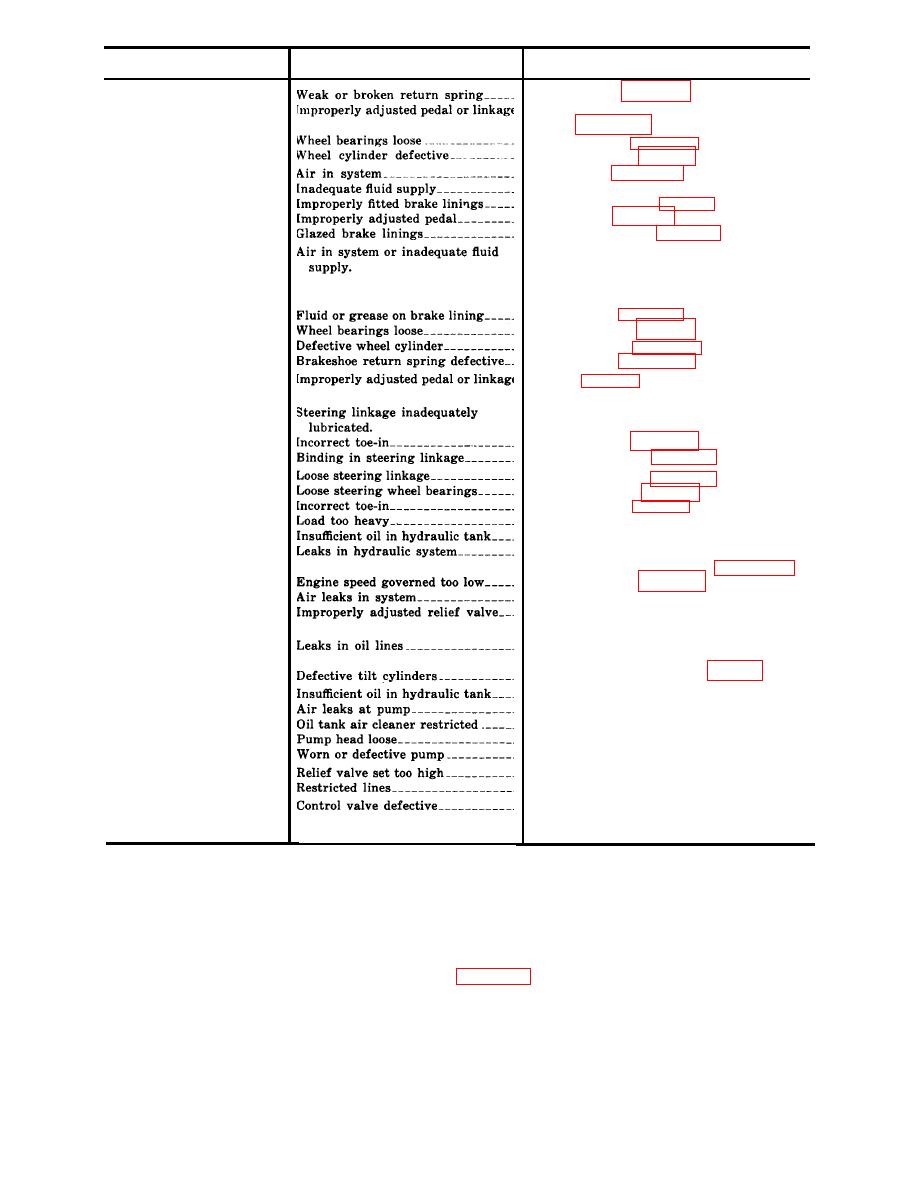

TABLE 1 TROUBLESHOOTING CHART - CONT |

|

||

| ||||||||||

|

|

Cause

Trouble

Remedy

Brake drag - - - - - - - - - - - - - - - - - - -

Replace spring (para. 51).

Adjust pedal for free travel of inch at pedal

pads (para. 54).

Adjust bearings (para. 55).

Replace cylinder (para. 53).

Bleed system (para. 52).

Spongy or soft brake pedal- - - -

Fill master brake cylinder.

Replace brakeshoes (para. 51).

Adjust pedal (para. 54).

Replace brakeshoes (para. 51).

Excessive pedal travel

Pump brake pedal several times. If pedal builds

required to apply brakes.

up to normal travel, bleed brake system. If

normal travel does not occur, fill master

brake cylinder.

Truck pulls to one side - - - - - -

Replace lining (para. 51).

Adjust bearings (para. 55).

Replace cylinder (para. 53).

Replace spring (para. 51).

Adjust (para. 46).

Creeper pedal mechanism

not operating properly.

Lubricate as shown on LO 10-3930-235-20 ).

Difficult steering - - - - - - - - - - - - -

Adjust the rods (para. 57).

Inspect and correct (para. 56).

Inspect and correct (para. 56).

Erratic steering control - - - - - -

Adjust bearings (para. 55).

Adjust the rods (par. 57).

Unable to lift or tilt load- - - -

Lighten load to 4000 lbs.

Fill as prescribed in LO 10-3930-235-20.

Inspect fittings and hose. Tighten connections.

Install new hose if necessary (para. 67).

Lift and tilt too slow - - - - - - -

Adjust governor (para. 28).

T'ighten all connections.

Report to direct support maintenance-per-

sonnel.

Load creeps tilting ---------

Tighten all connections or replace damaged

lines.

Replace defective cylinders (para. 62).

Noisy hydraulic pump ______

Fill as prescribed in LO 10-3930-235-20.

Tighten intake connections at pump.

Clean breather cap.

Tighten screws.

Report to direct support maintenance personnel.

Report to direct support maintenance personnel.

Oil overheating - - - - - - - - -

Locate restriction and correct.

Lift mechanism lifts but

Report to direct support maintenance personnel,

will not lower load.

Section IV. ENGINE

for positive forced feed lubrication to the

16. General

crankshaft bearings, connecting rod bearings,

The engine is a Continental model FS162,

camshaft bushing, and valve tappets. The

four cylinder, liquid tooled, L-head gasoline

engine and its accessories are illustrated in

figures 4 and 5.

type. It is lubricated by a gear-type oil pump

AGO 6217A

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |