|

|||

|

|

|||

|

Page Title:

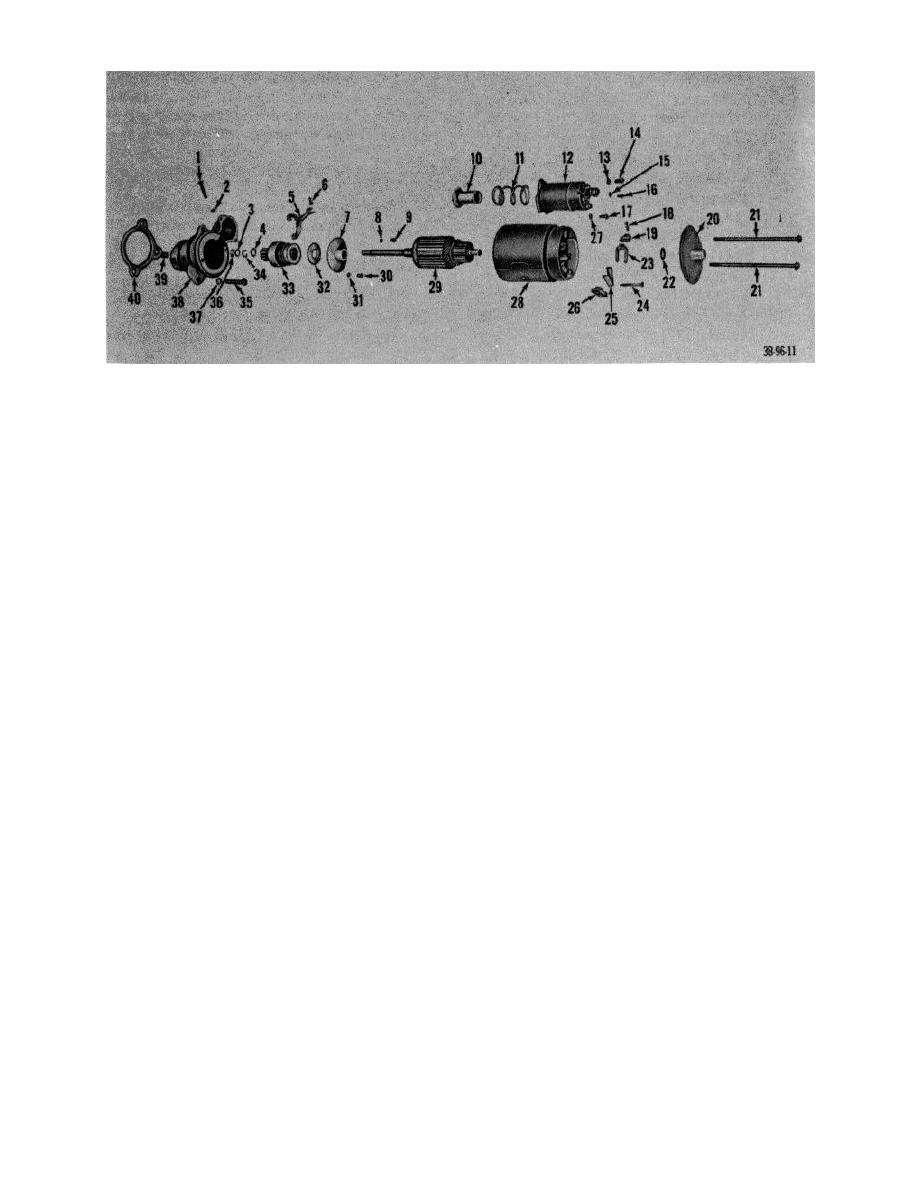

Figure 23. Starting motor, exploded view. |

|

||

| ||||||||||

|

|

1

Bolt, shoulder, drive lever

21

Bolts

2

Washer

22

Washer, brake, commutator end

3

Collar, thrust

23

Holder, brush, ground

4

Collar, pinion top

24

Pin

5

Lever, assembly, drive

25

Spring, brush

6

Pin, spring, lever-to-plunger

26

Holder, brush, insulated

7

Bearing, sleeve, center

27

Lockwasher

8

Lockwasher

28

Housing

9

Screw

29

Armature

10

Plunger

30

Screw

11

Spring, compression, plunger return

31

Lockwasher

12

Relay, solenoid, starter

32

Washer

13

Lockwasher

33

Drive assembly

14

Screw

34

Ring, retainer

15

Washer

35

Capscrew

16

Screw

36

Nut

17

Screw

37

Lockwasher

18

Screw, brush attaching

38

Housing, drive

19

Brush, contact

39

Bearing, sleeve, drive end

20

Frame, commutator end

40

Adapter, starting motor

Figure 23. Starting motor, exploded view.

brushes if worn beyond one-half original

(7) Remove screws (86) and washers (87) that

length.

attach bearing plate (12) to drive end frame and

(c) Be certain that brush holders are not bent or

remove plate.

(8) Remove gasket (11), bearing (10), felt retaining

damaged in any manner and that brush

plate (9) and washer (8) from drive end frame

springs are not corroded or distorted. Check

(7).

for brush spring tension of 28 ounces.

c. Cleaning. Using air hose or clean cloths, remove

(d) Using a testing device consisting of a lamp

all dirt from component parts of generator before

wired in series with two probes and the source

inspecting them.

of electricity, inspect the field coils for proper

d. Inspection, Testing, and Repair.

ground. Before testing, be sure brushes are

(1) Frame, field coils, brushes, springs, leads,

not touching frame or pole shoes, then

proceed as follows: Touch one probe to

connections, and terminal stud.

terminal stud and the other probe to an

(a) Inspect field coils for worn or frayed

unpainted spot on the frame. Should the lamp

insulation; corroded, loose, or burned terminal

light, the current in the field coils is being

stud assembly; and loose or corroded

grounded before it completes the circuit.

connections.

(b) Inspect brushes for excessive wear, broken or

frayed leads, and oil saturation. Replace

AGO 7010A

34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |