|

|||

|

|

|||

|

Page Title:

APPENDIX II MAINTENANCE ALLOCATION CHART |

|

||

| ||||||||||

|

|

TM 10-3930-222-20

APPENDIX II

MAINTENANCE ALLOCATION CHART

e. Replace. To substitute serviceable assemblies,

1. This appendix was prepared 6 December 1962

subassemblies,

and

parts

for

unserviceable

and lists all maintenance operations to be performed by

components.

the applicable echelons. These allocations are based

f. Repair.

To restore an item to serviceable

on skills, tools, test equipment and the time required or

condition through correction of a specific failure or

available in the average TOE organization.

unserviceable condition. This function includes but is

2. The sequence of entries coincides with the

not limited to, inspecting, cleaning, preserving,

sequence followed in Appendix III, Repair Parts and

adjusting, replacing, welding, riveting, and straightening.

Special Tools List.

g. Aline.

To adjust two or more parts and/or

3. This appendix is a guide in performing

assemblies of an electrical precision, mechanical, or

maintenance operations; for authorization for specific

steering system ,so that their functions are properly

repair parts, refer to Appendix III, Repair Parts and,

synchronized.

Special Tools List.

h. Overhaul. To restore an item to a completely

4. The explanations listed below define the terms

serviceable condition as prescribed by serviceability

used in this maintenance allocation chart:

standards developed and published by heads of

a. Clean. To perform major cleaning internally or

technical services.

This is accomplished through

with disassembly.

employment of the technique of "Inspect and Repair

b. Adjust.

To regulate periodically to prevent

Only as Necessary" (IROAN). Maximum utilization of

malfunctioning.

diagnostic and test equipment is combined with

c. Inspect. To verify serviceability and to detect

minimum disassembly of the item during the overhaul

electrical or mechanical failure by scrutiny.

operation.

d. Test.

To verify serviceability and to detect

electrical or mechanical failure by use of special

equipment such as gages, meters, etc.

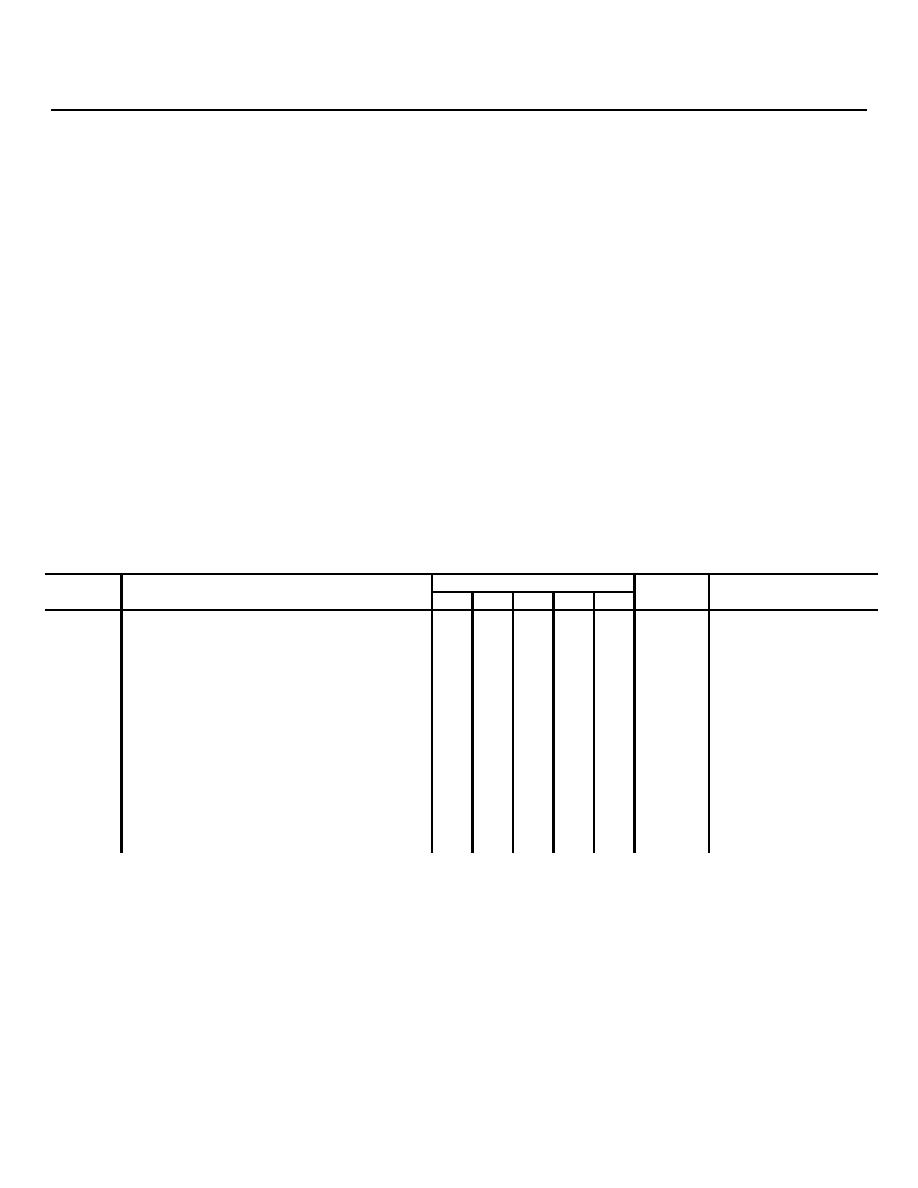

Group

Echelon

Tools

Number

Component and Related Operations

1

2

3

4

5

Required

Remarks

01

ENGINE

ENGINE ASSEMBLY

--------

Compression, Vacuum,

Test

--

X

Testing

Replace

--

--

X

Overhaul

--

--

--

X

BLOCK, engine

Inspect

--

--

--

X

Overhaul (Rebore)

--

--

--

--

X

--------

Reboring may be

accomplished at

4th echelon if

facilities are

available from

Government or

commercial sources.

143

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |