|

|||

|

|

|||

|

Page Title:

Section III. OPERATION UNDER USUAL CONDITIONS |

|

||

| ||||||||||

|

|

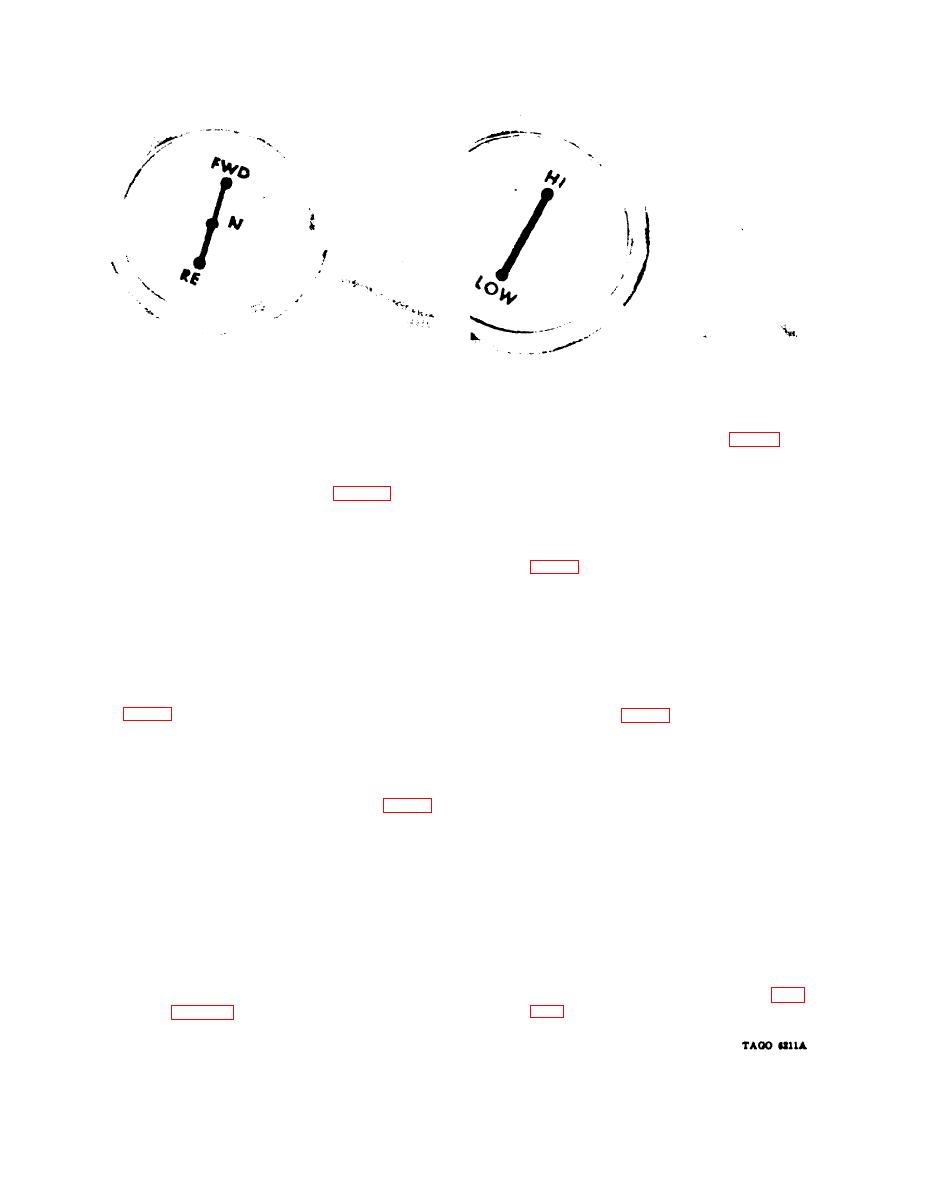

Figure 6. Direction control lever.

Figure 7. High- and low-speed lever.

move the forks closer together. Turn the crank

counterclockwise to move the forks further

apart.

located on the instrument panel at the right of

12. Instruments

the water temperature gage. This gage indi-

cates the amount of gasoline in the fuel tank.

The capacity of the fuel tank is 14 gallons.

cated on the instrument panel to the left and

e. Converter Oil Temperature Warning

above the steering column. The ammeter indi-

Light. The converter oil temperature warning

cates the amount of current flowing to or being

withdrawn from the storage battery. When the

light (8, fig. 4) is located on the instrument

engine is started, the needle will move momen-

panel to the left of the ignition switch (9). The

tarily far to the charge side of the dial and then

warning light glows red when the transmission

return to a center position or slightly to the

temperature is too high for safe operation of

charge side. If the ammeter shows a constant

the truck. If the light glows, stop the engine

discharge, stop the engine and report the

immediately and report the trouble to the

trouble to the proper authority.

proper authority.

b. Oil Pressure Gage. The oil pressure gage

f. Water Temperature Gage. The water

(3, fig. 4) is located on the instrument panel

temperature gage (5, fig. 4) is located on the

at the right of the ammeter. This gage indi-

instrument panel to the right of the hour

cates the pounds per square inch of oil pressure

meter. This gage indicates engine coolant

in the engine lubrication system. Normal op-

temperature on a dial marked C, NORMAL, and

erating pressure is 20 to 30 psi at 2,000 rpm.

H. During operation, the needle should move

into the NORMAL area. If the needle fails to

move into this area after the engine has been

is located on the instrument panel to the right

operated for a reasonable time, or moves into

of the oil pressure gage. This meter indicates

the H area, stop the engine and report the

the total number of hours that the engine has

trouble to the proper authority.

been in operation.

OPERATION UNDER USUAL CONDITIONS

Section III.

b. Instructions.

13. Starting

a. Before-Operation Services. Perform the

(1) Set the handbrake by pulling up and

back on the handbrake lever (par.

before-operation services listed in the operator's

1 1h ) .

checklist (par. 24).

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |