|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

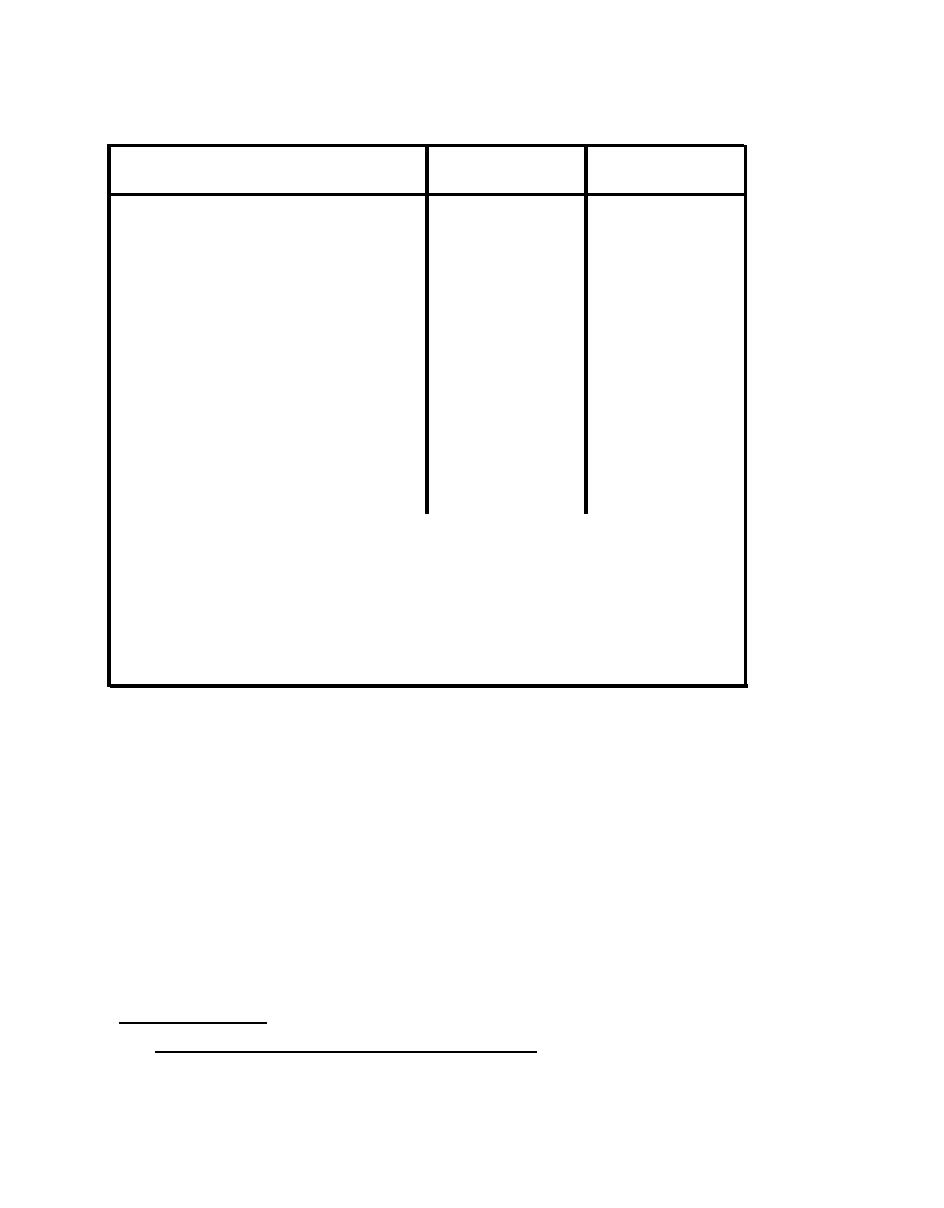

TB 43-0142

Table A-1. Sheave Diameters

Minimum

Critical

Diameter2

Diameter,

Rope Construction

20d

34d

6 X 19 Scale

6 X 16 Filler Wire

30d

16d

6 X 19 Warrington

30d

16d

30d

Flattened Strand

26d

16d

8 X 19 Scale

8 X 19 Filler Wire

26d

8 X 22 Filler Wire

23d

8 X 19 Wanington

21d

14d

8 X 37 Scale

14d

18d

8 X 41

18d

6 X 6 X 7 Filler Rope

...

10d

1Measure

sheave diameter between the bottom of the groves on opposite

sides and not the overall flange diameter.

2Critical

diameter is the diameter of the smallest bend for a given wire rope

which permits the wires and strands to adjust themselves by relative

movement while remaining in their normal position.

3Military

specifications normally specify 16 by 37 inch wire rope with an 16d

sheave at the time of end item procurement. (e.g., 6 by 37 by 1/2 inch

diameter wire rope. [18 by 1/2 = 9 inch sheave diameter]).

(7) Rope properly secured to the drum. When the crane or hoist is in its extreme upright

and extended position and the hook is touching the ground, there shall be two full wraps of cable

remaining on the drum. The same limits prevail for the boom hoist drum rope when the boom is in its

extreme low position. Pay particular attention to those positions of the rope subjected to reverse

bends and operation over small diameter drums and sheaves.

NOTE

The continued use of wire rope of reduced

diameter will cause sheave distortion.

(8) Compatibility with type of use. For example, rope used on ingot pouring cranes and

cranes exposed to high heat must have a steel wire core. A corrosive resistant core and/or

galvanized finish is required for an excessively corrosive exposure. Fiber core wire rope slings of all

grades should not be exposed to temperatures in excess of 200 F.

(9)

Excessive wear of chain-drive sprockets and excessive chain stretch.

d. Hydraulic Systems.

(1) Hydraulic Hoses, Fillings, and Tubing Inspection. All hydraulic hoses, fittings and

rigid tube lines should be inspected. Particular attention should be given to those hoses which flex

in normal operation of crane functions. Any deterioration should be carefully examined and

A-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |