|

|||

|

|

|||

|

Page Title:

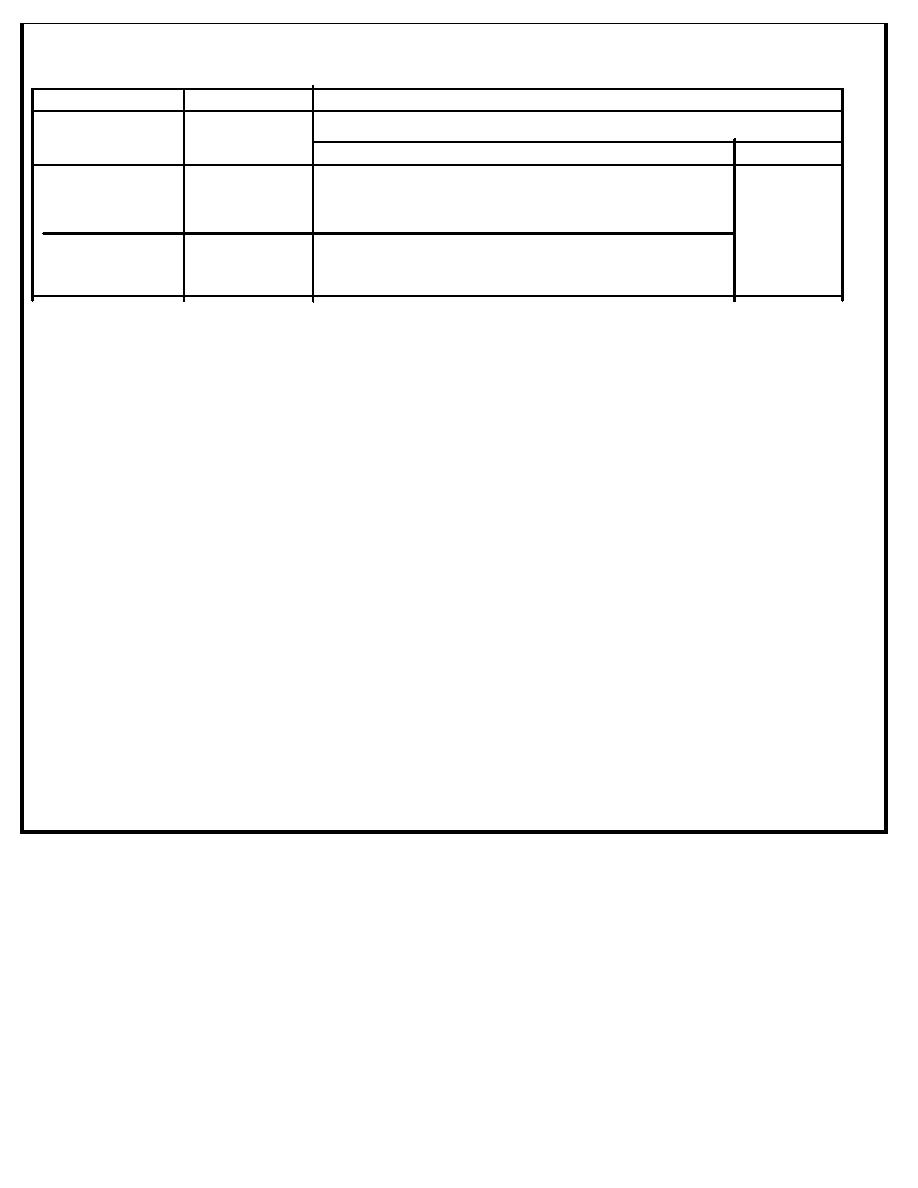

FOR OPERATION OF EQUIPMENT INFOR OPERATION OF EQUIPMENT IN PROTRACTED COLD TEMPERATURES BELOW 150F (-26C) |

|

||

| ||||||||||

|

|

* KEY -

EXPECTED TEMPERATURES

Above +150F

+40to -15F

+40to -650F

LUBRICANTS

CAPACITY

(Above -9C)

(+4to -260C)

(+4to -54C) INTERVALS

BFS - Brake Fluid,

Automotive

ALL TEMPERATURES

- Brake Master

3 pts.

Cylinder

(1.4L)

GAA- Grease,

Automotive

ALL TEMPERATURES

and Artillery

*See Note 6 for lubricant specification number

bring oil level to level plug opening.

1.

FOR OPERATION OF EQUIPMENT IN

6. LUBRICANTS. The following is a list of lubricants

PROTRACTED COLD TEMPERATURES BELOW -

with military symbols and applicable specification

numbers.

temperatures above -150F (-260C) Relubricate with

OE/HDO

MIL-L-2104

lubricants specified in Key for temperatures below -15F

GO

MIL-L-2105

(-260C) If OEA lubricant is required to meet the

GAA

MIL-G-10924

temperature ranges prescribed in the Key, OEA lubricant

OEA

M I L-L-46167

is to be used in place of OE/HDO-10 lubricant for al

BFS

MIL-B-46176

temperature ranges where OE/HDO-10 is specified in

(SD), Type II

P-D-680

the Key.

Copy of this Lubrication Order will remain with the

2. OIL CAN POINTS. Each 250 hours lubricate seat

equipment at all times, instructions contained herein are

brake and hand brake linkage, accelerator pivot points,

mandatory. By order of the Secretary of the Army:

and al exposed adjusting threads with OE/HDO

3. HYDRAULIC RESERVOIR AND FILTERS. Check oil

JOHN A. WICKHAM, JR.

level each 50 hours Maintain oil level to "FULL" mark.

General, 'United States Army

Each 1000 hours drain reservoir, remove filter elements,

Chief of Staff

clean filter shells and install new filter elements.

OFFICIAL:

Reinstall drain plug and fill reservoir. Operate lift for 5

ROBERT M. JOYCE

minutes, check for leaks, check oil level and bring to

Major General, United States Army

"FULL" mark.

The Adjutant General

wheels, clean and inspect al parts, replace damaged or

DISTRIBUTION:

worn parts repack bearings, and assemble.

To be distributed in accordance with DA Form 12-25A,

5. DRIVE AXLE. Check level each 5( hours. Change

Operator and Organizational maintenance requirements

gear lubricant only where required by maintenance repair

for Fork Lift Trucks. TA 220598

action contamination by water, or other foreign material.

After refill, operate for five minutes, check for leaks and

LO 10-3930-615-12

*U.S. GOVERNMENT PRINTING OFFICE: 1984-420-903/241

CARD 4 OF 4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |